cosmos_275

Hot Rolled

- Joined

- Jun 9, 2015

I have a transformer for my new Doosan lathe. Ellison sold me an autotransformer to get the 3 phase 240 delta I have down to 220.

My speedio uses an isolation transformer and the X0 had to be connected to neutral to get the 3 phases to be equal.

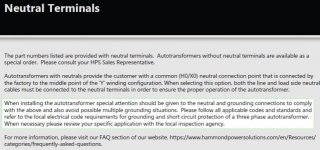

Correct my if I'm wrong, but I'd think this one would need X0 connected to neutral as well (Y030CECF3L0U):

https://documents.hammondpowersolut...e/Specialty/HPS-Autotransformers-Brochure.pdf

Manual says machine needs 6 awg. If the transformer gets a neutral, what awg does it need?

Thanks

My speedio uses an isolation transformer and the X0 had to be connected to neutral to get the 3 phases to be equal.

Correct my if I'm wrong, but I'd think this one would need X0 connected to neutral as well (Y030CECF3L0U):

https://documents.hammondpowersolut...e/Specialty/HPS-Autotransformers-Brochure.pdf

Manual says machine needs 6 awg. If the transformer gets a neutral, what awg does it need?

Thanks