cgrutt

Aluminum

- Joined

- Apr 7, 2016

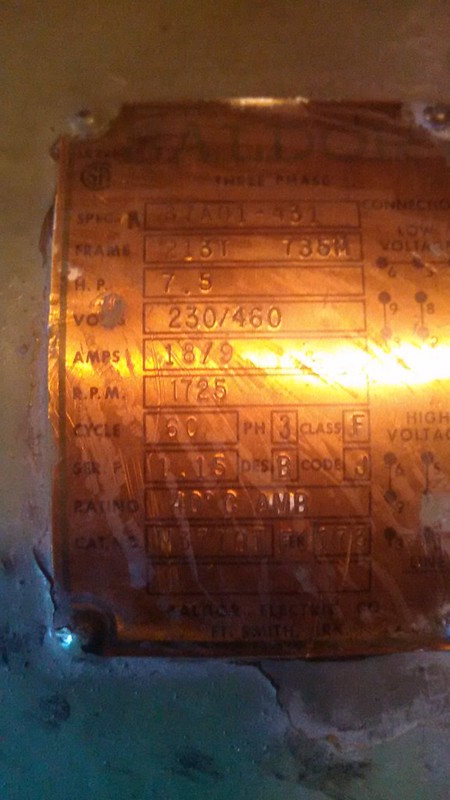

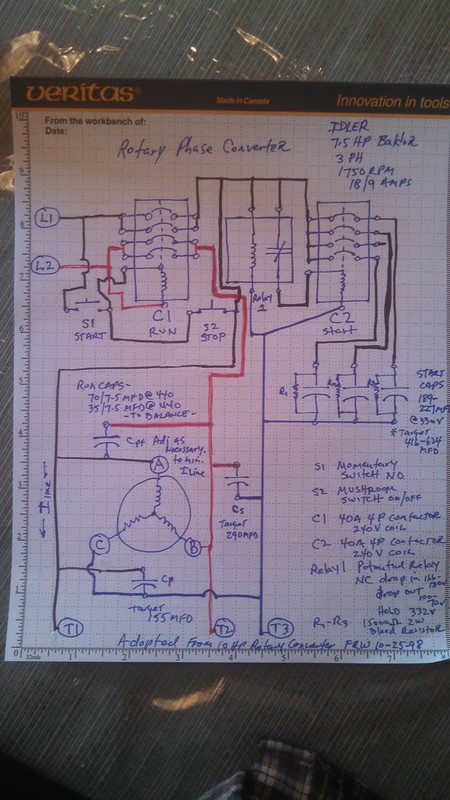

Picked up a Baldor 7.5 HP 3PH 1750 RPM motor to build a Rotary Phase Converter today. Want to build it to self start and with voltage balancing. Been reading a lot of great information within this forum and others and think I've got the basic gist of it but need help with choosing the right capacitors (I'm sure I'll need help with other stuff later, LOL).

So read in another post a "guideline" for capacitors for a generic 1 HP 3 PH RPC is 1 start capacitor of 100 MFD @ 250V and 2 run capacitors of 10 MFD of @ least 300 VAC and this guideline remains pretty much linear for larger motors. Based on this, I believe I will need 1 start cap of about 750 MFD @ 250 VAC and 2 run caps of about 75 MFD of @ least 300 VAC. Is this right so far?

I looked at some caps online and found some have multiple MFD ratings e.g., Jard #11952 start cap is rated 216-259 MFD @ 250V 11952 - Jard 11952 - 216 - 259 MFD Round Start Capacitor (25V) Do you use the low, high or maybe average MFD rating when choosing the correct cap? Would three of these run in parallel give me the approx. 750 MFD @ 250 VAC that I need based upon guideline?

Also for the Starter Cap, is it a good idea to use a "bleeder" resistor to discharge cap after RPC is running and it is taken out of circuit? If so, can anybody recommend the appropriate resistor to accomplish this?

As far as the run caps, will 2 of the Jard #12899 12899 - Jard 12899 - 8 MFD Round Run Capacitor (37V) be a good choice for my application?

Are these even the right caps to be looking at? Should I be looking at different styles, etc.?

Finally, do these capacitors provide the necessary "balancing" voltage for the "phantom" leg of the RPC.

Appreciate your help. Been reading about this for hours and haven't stumbled upon a cookie cutter parts list for a 7.5 HP RPC. If anybody has one, I'd appreciate it if you would point me in the right direction.

Thank you.

So read in another post a "guideline" for capacitors for a generic 1 HP 3 PH RPC is 1 start capacitor of 100 MFD @ 250V and 2 run capacitors of 10 MFD of @ least 300 VAC and this guideline remains pretty much linear for larger motors. Based on this, I believe I will need 1 start cap of about 750 MFD @ 250 VAC and 2 run caps of about 75 MFD of @ least 300 VAC. Is this right so far?

I looked at some caps online and found some have multiple MFD ratings e.g., Jard #11952 start cap is rated 216-259 MFD @ 250V 11952 - Jard 11952 - 216 - 259 MFD Round Start Capacitor (25V) Do you use the low, high or maybe average MFD rating when choosing the correct cap? Would three of these run in parallel give me the approx. 750 MFD @ 250 VAC that I need based upon guideline?

Also for the Starter Cap, is it a good idea to use a "bleeder" resistor to discharge cap after RPC is running and it is taken out of circuit? If so, can anybody recommend the appropriate resistor to accomplish this?

As far as the run caps, will 2 of the Jard #12899 12899 - Jard 12899 - 8 MFD Round Run Capacitor (37V) be a good choice for my application?

Are these even the right caps to be looking at? Should I be looking at different styles, etc.?

Finally, do these capacitors provide the necessary "balancing" voltage for the "phantom" leg of the RPC.

Appreciate your help. Been reading about this for hours and haven't stumbled upon a cookie cutter parts list for a 7.5 HP RPC. If anybody has one, I'd appreciate it if you would point me in the right direction.

Thank you.