You need to designated the source of the run commands which would be A001, A002, and A076. I typically do not run the VFD directly from the control panel, the WJ200 keypad is pretty poor. I typically use either 2 wire or 3 wire control and a remote speed pot. The motor 1 or 2 input only selects the parameter set to be used. You can try to setup the VFD with 2 wire control and use an external switch to trigger input 1 for forward, input 2 for reverse. You can program another input for the motor selection. You must select the run command source A002 and A202 = 01 as the input terminals in order to use a input to switch the motor parameters, but by doing so you inactivate the keypad run command so must use a programmed terminal input to issue the run command by using 2 wire or 3 wire control.

Also to get too a number of the WJ200 parameters you must first unlock the keypad.

1. Change B037 to "00" for full display of all functions. You must press both the up and down arrows to access single-digit edit mode since this feature is not accessible in the default basic display. You must change B037 before you can change B031.

AND THEN

2. Change B031 to "10". This unlocks all the high level program functions for editing. Then make the following program changes that are highlighted.

I would set A001 and A201 = 01 (Control terminal) if using an external speed pot

I would set A002 and A202 = 01 (Control terminal) if you want to use the control inputs as the command source

I would set A076 = 01 ([O] terminal (voltage in)) if using an external pot connected to the H, O and L input terminals.

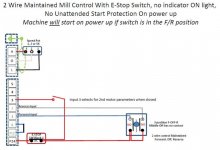

I would set C001 = 00 (FW:FORWARD Run/Stop)

I would set C002 = 01 (RV:Reverse Run/Stop)

I would set C003 = 08 Set (select) 2nd Motor Data

Connect a switch from input 1 to L to run forward, input 2 to run in reverse, input 3 to select motor 2 parameters. Get an inexpensive 1 or 2K speed pot for speed control connected to the H, O and L inputs.

I have a full parameter file for the WJ200 for a 3Hp mill, but this site download capacity is so small that it is next to worthless to attach a file. Basic schematic attached, you can use sink or source connections, my default is to use source because I use logic diodes in some of my designs.