adambomb777

Aluminum

- Joined

- Dec 21, 2012

- Location

- Newberry Springs, Ca

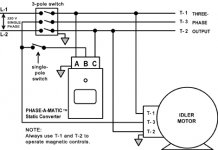

I just bought my first lathe to learn on. I have never used a lathe before. The lathe is a Delta 11" and I believe the tag on the motor says it is 1 1/2 hp. That would match what I've read about these lathes. In the cabinet the lathe came with a phase A matic static phase converter PAM-1200hd, horsepower range is 8 to 12. It is too big for my lathe motor. In the manual it has an option 2 where you use: Static Phase Converter used to start an Idler Motor, Idler Motor to power the load motor. Is this a good option? If so, What size motor would you recommend? What size machine motor would it comfortably run? I would like to buy other three phase machines later, but have no idea what power they would require. Any suggestions would be appreciated. Thanks.