jeff260z

Plastic

- Joined

- Oct 5, 2008

- Location

- New Brunswick, Canada

Hi all

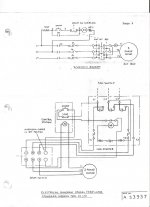

I bought a Standard Modern 1340 lathe that was wired 3 ph. It was missing the drum switch and motor so I bought a rebuilt 3HP single phase reversible 240 volt motor. I also bought a square D drum switch of ebay of cheap.

Here is my info...

Thanks

Jeffrey

I bought a Standard Modern 1340 lathe that was wired 3 ph. It was missing the drum switch and motor so I bought a rebuilt 3HP single phase reversible 240 volt motor. I also bought a square D drum switch of ebay of cheap.

Here is my info...

Thanks

Jeffrey