EnvisionIT

Plastic

- Joined

- Apr 30, 2019

Hi,

I have a new Martin shaper coming that requires 480 - 3ph power for a 7.5kva motor. From what I am reading the Martin has L1, L2, L3 and Ground, whereby the L1-3 are where I connect the 480v 3-ph power to.

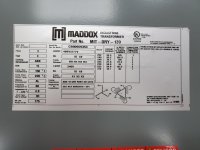

I purchased a new Maddox 3 - Phase 240V to 480 Y 277 Step up transformer and have a couple of quick questions. SKU MIT-DRY-139

I'm stepping up power from a Phase Perfect unit, so I have 3 hot leads and 1 ground from the PP unit to connect to the transformer at X1, X2, X3 and the Case ground.

The input voltage reported by the Phase Perfect is 246v and the output on each of my phases is 246/244/246.

Questions:

1. Regarding ground to the machine, the Transformer has H0, H1, H2, H3. Should I connect the ground wire from the Martin to the H0, and then add another wire from the case ground to H0? Reading on a variety of posts it is not clear on this item. I understand that I would connect H1,H2 and H3 to their respective L1/L3/L3 on the Martin.

2. The voltage from my phase perfect is slightly high i.e. 246. Should I move the transformer taps from #3 240v to #2 246v? Not sure if this is even necessary or just leave the taps at their current #3 position.

3. I have a spool of 10ga 4 conductor wire I use for my 240 - 3Ph machines, if I am reading my amp conversion formula's right, I should not draw more than 30A from the transformer to the machine at 7.5kva so that wire I'm assuming would be fine. I'll use a higher gauge to connect the transformer to the Phase Perfect unit.

Here are pictures of the unit and the label.

Thanks for any help.

I have a new Martin shaper coming that requires 480 - 3ph power for a 7.5kva motor. From what I am reading the Martin has L1, L2, L3 and Ground, whereby the L1-3 are where I connect the 480v 3-ph power to.

I purchased a new Maddox 3 - Phase 240V to 480 Y 277 Step up transformer and have a couple of quick questions. SKU MIT-DRY-139

I'm stepping up power from a Phase Perfect unit, so I have 3 hot leads and 1 ground from the PP unit to connect to the transformer at X1, X2, X3 and the Case ground.

The input voltage reported by the Phase Perfect is 246v and the output on each of my phases is 246/244/246.

Questions:

1. Regarding ground to the machine, the Transformer has H0, H1, H2, H3. Should I connect the ground wire from the Martin to the H0, and then add another wire from the case ground to H0? Reading on a variety of posts it is not clear on this item. I understand that I would connect H1,H2 and H3 to their respective L1/L3/L3 on the Martin.

2. The voltage from my phase perfect is slightly high i.e. 246. Should I move the transformer taps from #3 240v to #2 246v? Not sure if this is even necessary or just leave the taps at their current #3 position.

3. I have a spool of 10ga 4 conductor wire I use for my 240 - 3Ph machines, if I am reading my amp conversion formula's right, I should not draw more than 30A from the transformer to the machine at 7.5kva so that wire I'm assuming would be fine. I'll use a higher gauge to connect the transformer to the Phase Perfect unit.

Here are pictures of the unit and the label.

Thanks for any help.