richard newman

Titanium

- Joined

- Jul 28, 2006

- Location

- rochester, ny

I finally got my resaw power feeder up and running, thought I'd post some pix. It fed really smoothly and easily, could just keep blanks running thru one after another (butted up). SO MUCH faster, easier, and more accurate than hand feeding, wish I'd done it years ago.

Actually worked much better than I'd expected, held tolerance of +/- .003". I was sawing 4' x 3" laminations, a range of .100" - .350" from stock up to 3" thick, walnut, cherry, maple and mahogany. Ran stuff thru at 4 - 8 fpm, got a textured surface that cleaned up with a .005 pass/side on the planer or sander. Makes that operation go much faster also.

I used a 1/4 hp dc gear motor 8 rpm output. The drive roller uses 5-1/2"od x 2" wide 65 durometer urethane tires from Weinig. Had to cut one in half to make a 3" wide roller, that was the hardest part of the job - what a lousy material to turn!

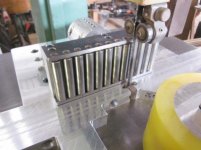

5/8 od rollers in 1/4" bronze sleeve bearings for the fence. Probably didn't need as many as I used. The fence shaft is bored 1/4-20 for a fine adjuster to be added later, altho it was easy to dial in the fence using dial calipers in depth mode.

The feed roll/motor unit pivots at the end of the arms that act as out-feed tables. Feed pressure is with an 1-1/16" air cylinder, at 50-60 psi. I was worried that the roller would slam in as the work exited, but it just kind of walks down, except with really thick stock which requires releasing pressure after the cut finishes. Butting up stock eliminates the problem.

Most of the materials, motor, and controller were from the scrap yard or ebay bargains, kept the cost very reasonable (except of course for all the time!)

It was so relaxing and satisfying to use, i was disappointed to be done so soon, felt like sawing up all the wood in the shop.

Actually worked much better than I'd expected, held tolerance of +/- .003". I was sawing 4' x 3" laminations, a range of .100" - .350" from stock up to 3" thick, walnut, cherry, maple and mahogany. Ran stuff thru at 4 - 8 fpm, got a textured surface that cleaned up with a .005 pass/side on the planer or sander. Makes that operation go much faster also.

I used a 1/4 hp dc gear motor 8 rpm output. The drive roller uses 5-1/2"od x 2" wide 65 durometer urethane tires from Weinig. Had to cut one in half to make a 3" wide roller, that was the hardest part of the job - what a lousy material to turn!

5/8 od rollers in 1/4" bronze sleeve bearings for the fence. Probably didn't need as many as I used. The fence shaft is bored 1/4-20 for a fine adjuster to be added later, altho it was easy to dial in the fence using dial calipers in depth mode.

The feed roll/motor unit pivots at the end of the arms that act as out-feed tables. Feed pressure is with an 1-1/16" air cylinder, at 50-60 psi. I was worried that the roller would slam in as the work exited, but it just kind of walks down, except with really thick stock which requires releasing pressure after the cut finishes. Butting up stock eliminates the problem.

Most of the materials, motor, and controller were from the scrap yard or ebay bargains, kept the cost very reasonable (except of course for all the time!)

It was so relaxing and satisfying to use, i was disappointed to be done so soon, felt like sawing up all the wood in the shop.

). But the Al is going to erode.

). But the Al is going to erode.