Hello all,

This is my first post of many. I inherited my father's workshop full of tools, emco lathe, burke no. 4 horizontal mill, rockwell bandsaw, rockwell delta unisaw, and few other pieces. Except for the lathe, all other tools are in various stages of project completion status.

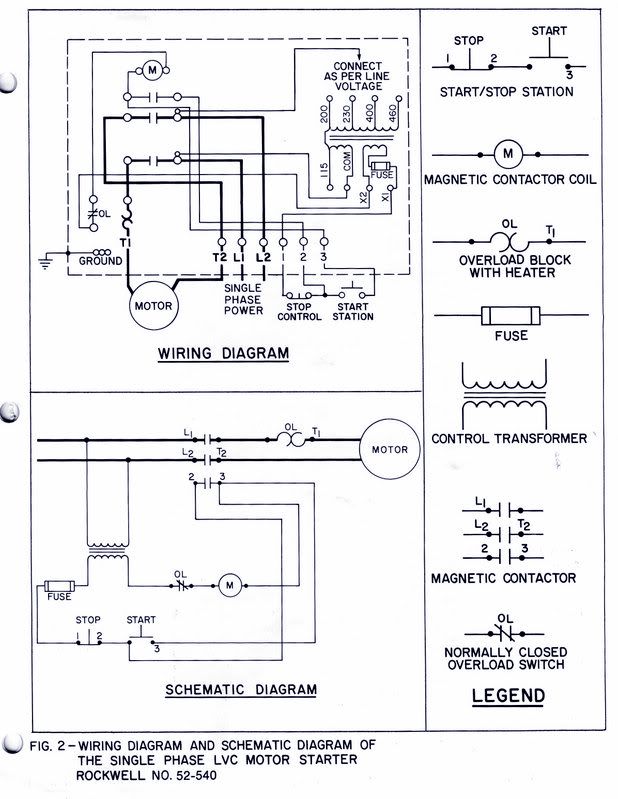

Right now I want to get the saw going. It came with a 3ph baldor bullet motor, and my father bought a used but in great shape rockwell 1ph 230V 3hp motor for his house wiring. I have gathered all the parts I could find, and it appears that I have everything together except for the controls and wiring. I'm a civil engineer and former 6th period union apprentice carpenter, good with tools, auto engine building, 12v boat wiring & electronics, but my electrical knowledge of electric service wiring is very limited.

I have a cutler-hammer manual nema size 0 motor 3ph starter that I assume came with the saw, photos of starter and motor attached.

Can I use this starter, or do I need something else. I will most likely not be doing anything heavy with the saw, probably some cabinetry, and some boat related starboard poly board fishing storage. I wrote an ebay vendor selling a magnetic starter assembly and he called be back and was generous with his time, this was before I found the manual starter switch, and he said many people in residential applications just use a normal switch and use a low amp circuit breaker at the main panel, in this case maybe a 12.5 amp one.

If possible I would like to use the cutler-hammer one because it's heavy duty and offers overload protection, I found out that the unisaw motors are costly and I don't want to fry this one or get hurt.

Thanks for your time and I look forward to participating.

Rob Lee, aka toothy (my cat's name and workshop buddy)

This is my first post of many. I inherited my father's workshop full of tools, emco lathe, burke no. 4 horizontal mill, rockwell bandsaw, rockwell delta unisaw, and few other pieces. Except for the lathe, all other tools are in various stages of project completion status.

Right now I want to get the saw going. It came with a 3ph baldor bullet motor, and my father bought a used but in great shape rockwell 1ph 230V 3hp motor for his house wiring. I have gathered all the parts I could find, and it appears that I have everything together except for the controls and wiring. I'm a civil engineer and former 6th period union apprentice carpenter, good with tools, auto engine building, 12v boat wiring & electronics, but my electrical knowledge of electric service wiring is very limited.

I have a cutler-hammer manual nema size 0 motor 3ph starter that I assume came with the saw, photos of starter and motor attached.

Can I use this starter, or do I need something else. I will most likely not be doing anything heavy with the saw, probably some cabinetry, and some boat related starboard poly board fishing storage. I wrote an ebay vendor selling a magnetic starter assembly and he called be back and was generous with his time, this was before I found the manual starter switch, and he said many people in residential applications just use a normal switch and use a low amp circuit breaker at the main panel, in this case maybe a 12.5 amp one.

If possible I would like to use the cutler-hammer one because it's heavy duty and offers overload protection, I found out that the unisaw motors are costly and I don't want to fry this one or get hurt.

Thanks for your time and I look forward to participating.

Rob Lee, aka toothy (my cat's name and workshop buddy)