mhajicek

Diamond

- Joined

- May 11, 2017

- Location

- Maple Grove, MN, USA

Maybe I'm just not getting you. I have no idea where your 5% is coming from.Been a few years ago so I got something mixed up . Regardless to come up with $4,000 you would have to sell $80,000 worth of product @ %5 net. Whats so hard to understand about that? Unless of course your business is the only one whose gross sales = 100% net or maybe you just find money ,I guess that would be 100% net.

Option 1: Spend $4000 and have the brackets.

Option 2: Make the brackets, don't spend $4000, but spend the cost of your labor and materials.

There should be no other numbers involved. If you're talking about the cost justification of buying the brackets, that's a completely different matter.

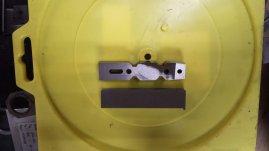

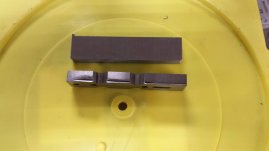

Like for me, I just bought a pair of 4" vises for about $600. I can easily justify that, because it will improve my output by far more than that cost over the life of the vises, but that doesn't factor into the decision about make vs. buy. If I were to make them, counting the value of my time plus materials, they would cost me several thousand dollars to make. They'd still pay themselves off, but making them would be the stupid choice in that case. How much money I can make with them doesn't change that.