Azoth

Aluminum

- Joined

- May 10, 2019

- Location

- Houston, TX

I have a Mazak Nexus 700D-II vmc with a Matrix Nexus Controller.

In my Tool Data page I am missing the "Tool Add" soft key.

On my Integrex I can duplicate the tool using this "Tool Add" soft key so multiple diameter offsets can be used on a single Tool by assigning an ID Code (letter A-Z) and calling up the tool (eg T1.1 - T1.26)

If I remember right, conventionally on Fanuc you can call up unique Diameter and Height offsets in eia programs simply by calling H1 or H11 or H200, but this isn't allowed on this machine either (still using eia programs). It has 2000 offsets available, but only 40 tools and no matter what D offset I put in the g-code, Mazak ignores it and refers to the Tool Data page.

On my Nexus I am able to assign ID Codes and I can call up the specific Tool (eg tool 35 id code G can be called up with T35.7) but I cannot assign multiple letters to the same tool. I must instead stop my program and manually adjust my offset back and forth.

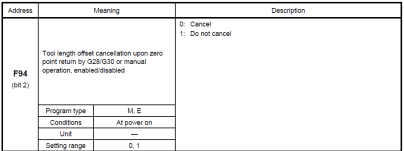

I have checked my parameter book and the parameters that looked related didn't make a difference. And I'm not seeing anything stand out when comparing the Options displayed on my Nexus vs Integrex.

Does anyone know if this function is behind a parameter? or a paywall? or simply not an option on this controller?

In my Tool Data page I am missing the "Tool Add" soft key.

On my Integrex I can duplicate the tool using this "Tool Add" soft key so multiple diameter offsets can be used on a single Tool by assigning an ID Code (letter A-Z) and calling up the tool (eg T1.1 - T1.26)

If I remember right, conventionally on Fanuc you can call up unique Diameter and Height offsets in eia programs simply by calling H1 or H11 or H200, but this isn't allowed on this machine either (still using eia programs). It has 2000 offsets available, but only 40 tools and no matter what D offset I put in the g-code, Mazak ignores it and refers to the Tool Data page.

On my Nexus I am able to assign ID Codes and I can call up the specific Tool (eg tool 35 id code G can be called up with T35.7) but I cannot assign multiple letters to the same tool. I must instead stop my program and manually adjust my offset back and forth.

I have checked my parameter book and the parameters that looked related didn't make a difference. And I'm not seeing anything stand out when comparing the Options displayed on my Nexus vs Integrex.

Does anyone know if this function is behind a parameter? or a paywall? or simply not an option on this controller?