Hello everyone,

I'm resurrecting some old equipment that has not been used for >5 years.

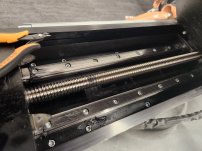

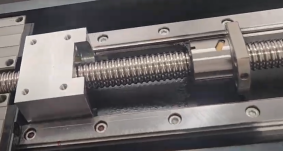

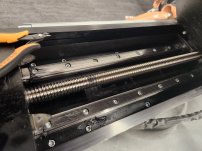

A linear actuator with what looks like a worm gear system and guiding rails.

It 90% working, but has some trouble during a small portion of the travel...about where you see the grease buildup on the worm. Also an another section it does a little short skip.

Any recommendations how to re-grease/clean this thing. What grease to use? Should I remove the buildup?

Specs:

speed, up to 2 cm/s

travel: 40cm

weight capacity: ~500lb

Thanks in advance.

P.S. Happy to read any source material...like Machinist Handbooks etc.

I'm resurrecting some old equipment that has not been used for >5 years.

A linear actuator with what looks like a worm gear system and guiding rails.

It 90% working, but has some trouble during a small portion of the travel...about where you see the grease buildup on the worm. Also an another section it does a little short skip.

Any recommendations how to re-grease/clean this thing. What grease to use? Should I remove the buildup?

Specs:

speed, up to 2 cm/s

travel: 40cm

weight capacity: ~500lb

Thanks in advance.

P.S. Happy to read any source material...like Machinist Handbooks etc.