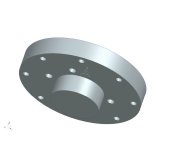

Can you make a plug to go inside the tube to prevent it from distorting where you clamp it?

Sacrificial aluminum fixture block with a hole bored into it, cut a slot to pinch it. Underside of the cap can rest on the block to hold it square, since the fixture is aluminum you should be able to drill or mill or undercut through your cap and into the fixture without causing a fuss.

Sacrificial aluminum fixture block with a hole bored into it, cut a slot to pinch it. Underside of the cap can rest on the block to hold it square, since the fixture is aluminum you should be able to drill or mill or undercut through your cap and into the fixture without causing a fuss.