riodeloso

Aluminum

- Joined

- Apr 23, 2010

- Location

- Ventura, CA

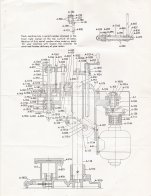

Found this little gem on Clist a few days ago...$50. Hamilton Vari-matic Sensitive Drill Press. The biggest little DP...probably weighs about 80-100 lbs. Infinitely variable speed from 800-8000 rpm via mechanical cone linkage. Needs some paint (stay tuned), but otherwise is in useable condition. And with a bonus RI 1hp 110V milling machine motor for $10 (no picture...but when the VN gets up and running, you'll see it). Even if the DP wasn't worth it, the motor was a great find!

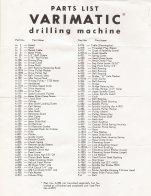

Anybody have a manual for this guy?

Anybody have a manual for this guy?

as my shop has moved twice since.

as my shop has moved twice since.