Hi thanks for adding me. This is a new problem and we are stumped.

Mazak Quickturn Nexus350myII

Using G-code Mastercam 2017. (Same issue with Mastercam X5)

Something changed we believe in a parameter or setting.In lathe mode used to be able to use 2 offsets for 1 tool. Eg. tool 1 offset 21 or T0121. For when cutting diameters with different tolerances with the same tool. But most recently when drilling with a U-drill then using it to rough bore.

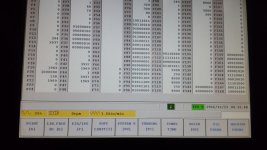

Now it seems the machine is completely disregarding the 21or offset number. It shows up on the screen in the tool details feild as T1 21. but doesn't actually apply the offset from register 21. No matter what, it always uses whats in register 1. This applies for all tools.Im just using tool 1 as an example.

Even if I choose to use one offset only but use offset 21 it still applies the register 1 offset.

Anyone ever run across this before?

Thanks

Mazak Quickturn Nexus350myII

Using G-code Mastercam 2017. (Same issue with Mastercam X5)

Something changed we believe in a parameter or setting.In lathe mode used to be able to use 2 offsets for 1 tool. Eg. tool 1 offset 21 or T0121. For when cutting diameters with different tolerances with the same tool. But most recently when drilling with a U-drill then using it to rough bore.

Now it seems the machine is completely disregarding the 21or offset number. It shows up on the screen in the tool details feild as T1 21. but doesn't actually apply the offset from register 21. No matter what, it always uses whats in register 1. This applies for all tools.Im just using tool 1 as an example.

Even if I choose to use one offset only but use offset 21 it still applies the register 1 offset.

Anyone ever run across this before?

Thanks