I think this machine can do some light milling also since the factory offered an X-Y table ,unless the table was merely for positioning of work-piece.

"Positioning", yes, and valuable. Milling? Not so much.

Better to take what you get for the other two DP and find a proper mill, Spud.

It isn't just about side-loads vs on-axis Mill vs DP. One also has to:

A) Keep the tooling from walking out of the spindle, and

B) most helpful to have advancing Z axis that can be utilized whilst in the cut, not 'just' X-Y.

C) NOT have a round-column vs box or dovetail that has nothing but friction to prevent it rotating under the sort of loads milling, not drilling, transmits to it.

EX: The AB5/S has the twin cutouts for MT5 drift key AND a wedge-lock retainer, much as MT spindle hor-bores have. There is no provision for a drawbar. Now.. it is 2017 here already.. How easy d'you suppose it is to FIND either the MT5 with the cutout for the retainer? Or even a retainer?

Yah NEED that. Morse Taper had already earned a reputation for otherwise walking out of the spindle somewhere around the late 1800's. Enter the B&S tapers that were to dominate milling-machine spindles for nearly a hundred years as better suited to the task. And they had drawbars, even so.

Back to the stout AB5/S. I have the round-column with the rectangular table. Ga-ron-tee the locks are no longer good enough to prevent the table rotating about the column if I tried to mill with it. Hard enough to keep the table centered over the base even just during its road-trip home.

I can improve on that. But even so, I'd be wiser to fab a bracing plate similar to an overarm support or shaper table support.

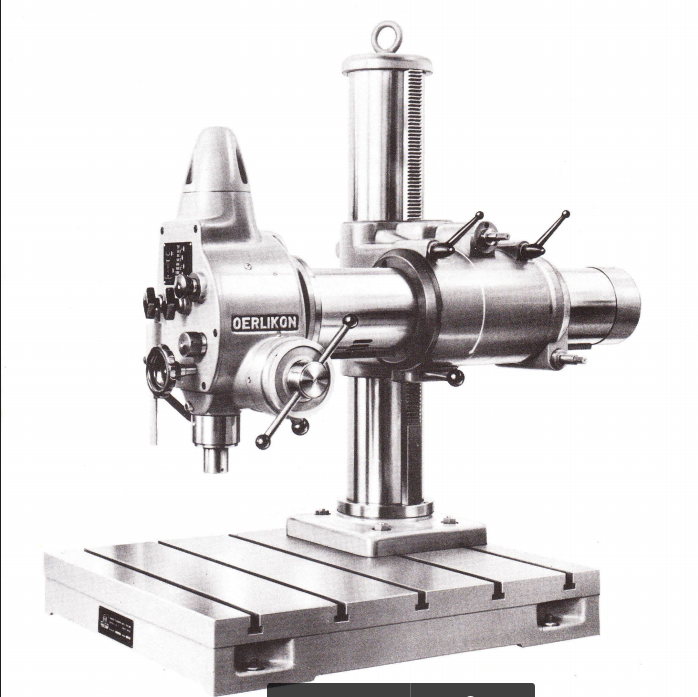

If useful? I'd still have no Z axis movable whilst in the cut. The quill does not replace a knee. WTH 7.5 HP AB5/S, vs 1 3/4 HP on the Quartet, and stout as it is, the AB5 quill still has a smaller diameter and 50% more stroke length to support than the Quartet's #9 B&S has. The Oerlikon doesn't really match either of those.

For me, "light" milling then, would be use of the Burke #4 instead of the "Quartet".

Drill presses make good drill presses. Most especially the three marque's under discussion, here.

Most Mills - even 'marginal' ones - make far the better mills than even these ones.

EG: It is generally cheaper and faster to have one of each than to mess about with attempted sex-change operations on either.

JM2CW. "I got mine", of course.