daredo222

Cast Iron

- Joined

- Mar 8, 2007

- Location

- Norwich U.K. & Marvao, Portugal

Cordless drill powered lifting device.

The only rotary table I have weighs 168lbs. / 76kgs. 12 stone in old money. It was a dangerous struggle to get it on & off a machine alone so I had to come up with some mechanical help. I could visualize several different approaches but the question was - how to power them? I thought about what prime mover I had available & realised I had a cordless drill. The photos show the result. I made this one year ago & have used it often, was a bit reluctant to post a lifting device because of safety issues but it has been well tested now.

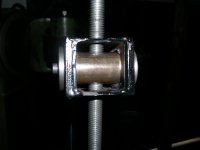

Basic principles - 12mm threaded rod threaded through a 1”/25mm dia. Aluminium Bronze trunnion.

Lifting eye free to swivel via a standard deep groove ball bearing.

Base plate & lifting arm are separate parts; the base plate can be left in place on the machine.

Very easy to make spare base plates & simply put the arm wherever you want it.

Finally, a portrait of the artist as an old man:

Workshop hoist - YouTube

Ray

The only rotary table I have weighs 168lbs. / 76kgs. 12 stone in old money. It was a dangerous struggle to get it on & off a machine alone so I had to come up with some mechanical help. I could visualize several different approaches but the question was - how to power them? I thought about what prime mover I had available & realised I had a cordless drill. The photos show the result. I made this one year ago & have used it often, was a bit reluctant to post a lifting device because of safety issues but it has been well tested now.

Basic principles - 12mm threaded rod threaded through a 1”/25mm dia. Aluminium Bronze trunnion.

Lifting eye free to swivel via a standard deep groove ball bearing.

Base plate & lifting arm are separate parts; the base plate can be left in place on the machine.

Very easy to make spare base plates & simply put the arm wherever you want it.

Finally, a portrait of the artist as an old man:

Workshop hoist - YouTube

Ray

Attachments

Last edited:

... permission to nick the idea guvna?

... permission to nick the idea guvna?