ZWelds

Plastic

- Joined

- Sep 15, 2014

Hi guys, first post here. I bought this haas for a 1000 bucks and got it into my tiny shop awhile back. Just got power to it and every thing seems to work except tool changer (have not tried it yet)which was surprising since it sat for 5 years with out power.

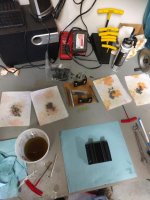

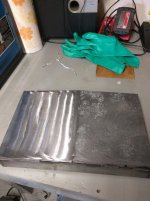

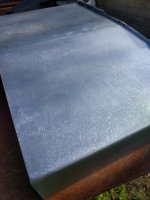

Started cleaning it this weekend. pulled the way covers off to find shavings every where under them, especially under the y axis, filled a shopvac. lucky it was all brass, no steel or stainless whatsoever. x axis wire conduit is broken in the usual so i ordered some from mcmaster to replace it. gonna order some new way cover seals tomorrow and do a little rework on the way covers, they are pretty rough. Ball screws seem ok, was getting about .0002 backlash on all axis.

The linear guide bearing block seals on all axis are shot and really need to be replaced. looks like i will need to remove the bearing blocks to do this.

Anybody here ever replaced the seals before?

Also have new oil lines on order from mcmaster.

Ill wait till the oil line and the wire conduit comes in and replace those, then figure out what I can do about the linear rail bearing seals, then rework the way covers.

Started cleaning it this weekend. pulled the way covers off to find shavings every where under them, especially under the y axis, filled a shopvac. lucky it was all brass, no steel or stainless whatsoever. x axis wire conduit is broken in the usual so i ordered some from mcmaster to replace it. gonna order some new way cover seals tomorrow and do a little rework on the way covers, they are pretty rough. Ball screws seem ok, was getting about .0002 backlash on all axis.

The linear guide bearing block seals on all axis are shot and really need to be replaced. looks like i will need to remove the bearing blocks to do this.

Anybody here ever replaced the seals before?

Also have new oil lines on order from mcmaster.

Ill wait till the oil line and the wire conduit comes in and replace those, then figure out what I can do about the linear rail bearing seals, then rework the way covers.