oldbrock

Hot Rolled

- Joined

- Feb 22, 2008

- Location

- Glade BC, Canada

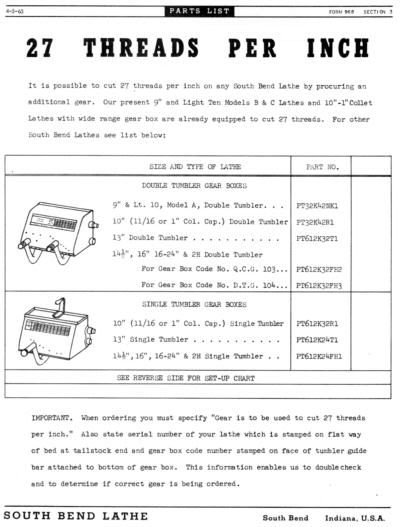

Had to screwcut a 1/8" pipe thread yesterday. Guess what? qcgb had 26 and 28 . the pitch is.03703" the closest feed on my 10K is A 2 which is .0379. So to hell with it, locked in the feed and taper attachment and forward reversed it. It actually fit, good job it is a short thread. Any better ideas out in South Bend land? Peter