spindle liners, that is.

I needed a 0.5" hex spindle liner spur of the moment for my Emco 365 a while back and decided to 3D print one. It worked great! 30" long they were printed in 5 sections each 6" tall using PETG filament on a Prusa MK3S+. Each section interlocked to the next with small holes on one piece and studs on the other. I then glued the sections together with Gorilla (polyurethane) glue. Since it was a hex shape the sections were keyed so the hex stayed lined up (oriented correctly with previous section) down the center. The print time was about 10 hours IIRC, but I printed it overnight so no biggie.

Our local JoAnn Fabrics has been selling a large lot of PETG and PLA Polaroid Filament in 1kg rolls for between $10 and $14 per spool. So while each liner takes nearly a full roll (~850g) of filament the cost of these liners is $10ea. There are two stores in my area but only one has the filament, not sure why really. Even at full price, a roll of PETG is typically around $30-$40.

I have a few polyurethane liners from Trusty Cook so my model was based on those. Those liners are about $250/per and take several days or more to get. Compared to the Trusy Cook liner which weighs in at 6.6 lbs, the PETG liner weighs 1.9 lbs. Makes them easy to push/pull into/out of the machine.

After running my job which used 4 - 12' bars (cut down to 36" and hand fed into liner (my bar feeder is me!), the liner looked fine. A bit dirty inside but no visible wear or issues that I could see. Time will tell how they hold up, but considering the forces I don't anticipate any problems with them. The PETG, if dropped on a concrete floor can break, its much more brittle than polyurethane, but as long as I don't fling them around it shouldn't be an issue. I can also print them in ABS which is even more pliable (softer) if brittleness becomes an issue.

The beauty is that if you need something quick (24 hours) or need an odd shape, this is a great way to go.

I have also experimented with printing a liner with minimal infill and then pouring Smooth-On 2-part polyurethane into it. This could work if you are concerned with durability. You want a slow-curing polyurethane (like Smooth-On 16hr set-up) otherwise the exo-thermic reaction of the polyurethane softens the PETG (or PLA) and the tube collapses. That was a mess!! But the slow set up poly works fine, fills in before set up and hardens nicely. A printed liner filled with poly would be as robust as the solid polyurethane from Trusty Cook, but would cost about 1/3 the price. I am going without filling them as they work fine as they are and easy peasy. If they break down the road I'll print another.

First 2 pictures are Trusty Cook liner on the left, the 0.5" Hex liner center and a 1" diameter round liner on the right that I printed.

-Tom

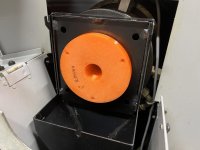

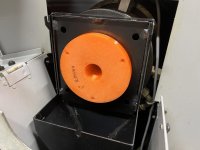

Sections before gluing:

I needed a 0.5" hex spindle liner spur of the moment for my Emco 365 a while back and decided to 3D print one. It worked great! 30" long they were printed in 5 sections each 6" tall using PETG filament on a Prusa MK3S+. Each section interlocked to the next with small holes on one piece and studs on the other. I then glued the sections together with Gorilla (polyurethane) glue. Since it was a hex shape the sections were keyed so the hex stayed lined up (oriented correctly with previous section) down the center. The print time was about 10 hours IIRC, but I printed it overnight so no biggie.

Our local JoAnn Fabrics has been selling a large lot of PETG and PLA Polaroid Filament in 1kg rolls for between $10 and $14 per spool. So while each liner takes nearly a full roll (~850g) of filament the cost of these liners is $10ea. There are two stores in my area but only one has the filament, not sure why really. Even at full price, a roll of PETG is typically around $30-$40.

I have a few polyurethane liners from Trusty Cook so my model was based on those. Those liners are about $250/per and take several days or more to get. Compared to the Trusy Cook liner which weighs in at 6.6 lbs, the PETG liner weighs 1.9 lbs. Makes them easy to push/pull into/out of the machine.

After running my job which used 4 - 12' bars (cut down to 36" and hand fed into liner (my bar feeder is me!), the liner looked fine. A bit dirty inside but no visible wear or issues that I could see. Time will tell how they hold up, but considering the forces I don't anticipate any problems with them. The PETG, if dropped on a concrete floor can break, its much more brittle than polyurethane, but as long as I don't fling them around it shouldn't be an issue. I can also print them in ABS which is even more pliable (softer) if brittleness becomes an issue.

The beauty is that if you need something quick (24 hours) or need an odd shape, this is a great way to go.

I have also experimented with printing a liner with minimal infill and then pouring Smooth-On 2-part polyurethane into it. This could work if you are concerned with durability. You want a slow-curing polyurethane (like Smooth-On 16hr set-up) otherwise the exo-thermic reaction of the polyurethane softens the PETG (or PLA) and the tube collapses. That was a mess!! But the slow set up poly works fine, fills in before set up and hardens nicely. A printed liner filled with poly would be as robust as the solid polyurethane from Trusty Cook, but would cost about 1/3 the price. I am going without filling them as they work fine as they are and easy peasy. If they break down the road I'll print another.

First 2 pictures are Trusty Cook liner on the left, the 0.5" Hex liner center and a 1" diameter round liner on the right that I printed.

-Tom

Sections before gluing:

Last edited: