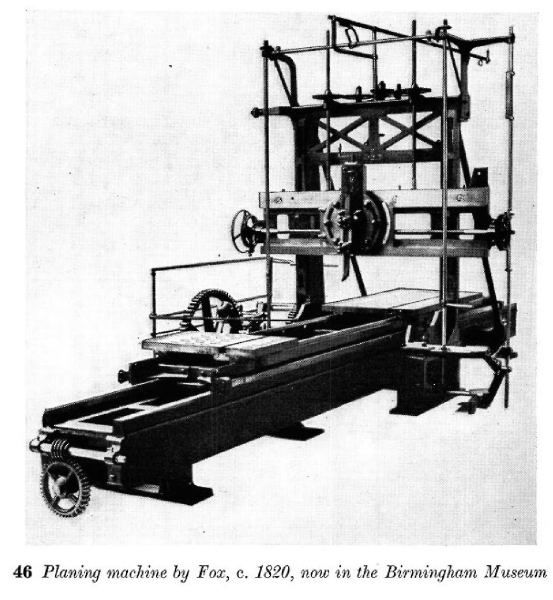

W Steeds' book includes a photo of a fine model of a small Fox planing machine in the Musée des arts et métiers in Paris. The date is given as c.1833. It appears to have a bevel cluster arrangement for reversing the table, as on Fox’s lathes.

The planer at Birmingham does

not use reversing bevels. Probably because it would have been out of the question to reverse the relatively heavy table and workpiece using simple dog clutches.

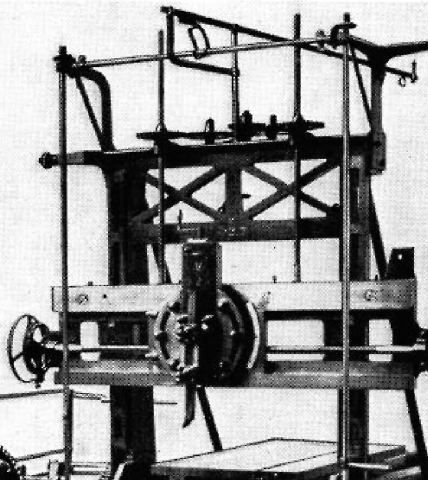

Instead, it had a reversing belt drive. The photo shows the driven pulleys, loose in the middle and fastened either side. They would be driven by a direct belt or a crossed belt (for reverse). The belt shifter loop can be seen at the top of the photo.

The pulley shaft drives a small pinion, being the start of a double reduction gear train.

It will get confusing, shortly. Referring to part of the photo from Rolt’s book:-

Note the slender horizontal shaft at the top, going from left to right. In the middle is what looks like a letter D, but is in fact a gear sector engaging a short rack (photo below). The rack moves another slender rod fore and aft, i.e. parallel with the axis of the machine's table. Near the far end of this is the belt shifting loop.

However, this means that the belt must be running at right angles to the machine’s axis, which is the wrong way. I’m stumped.

Let’s return to the easier stuff, before stalling again.

Going back to the slender horizontal shaft which operates the gear sector, this shaft has a bevel gear at each end, meshing with bevels at the top of vertical shafts. These shafts both have a short handle, allowing manual belt shifting. The one on the left must also be operated by an adjustable striker on the table. Probably not directly, but via one of Fox’s tumbling weighted levers. A weight is visible in the 'Rolt photo' in #26, but I have no more information about what’s going on over there.

I hoped the 1834 French drawings of a small Fox planer would help, but not at all. It does have a belt shifting system, and tumbling levers, but there the resemblance ends. Link below (note that there are several pages of drawings):-

CNUM - BSPI.33 : pl.580