- Joined

- May 14, 2009

By Susan Woods, Contributing Editor

Click Here for a free subscription to Cutting Tool Engineering magazine.

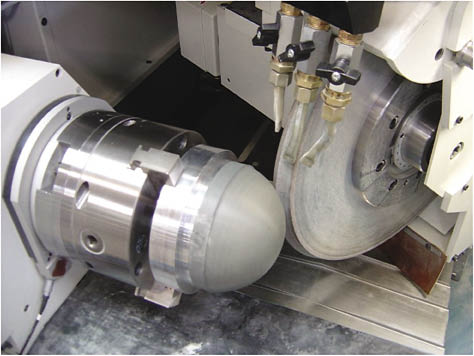

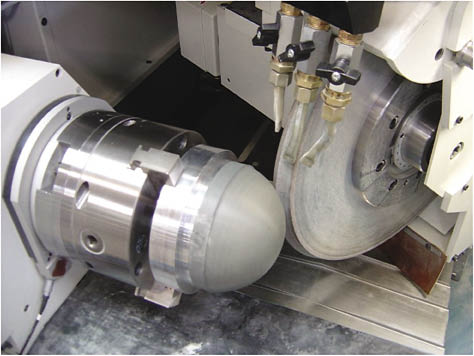

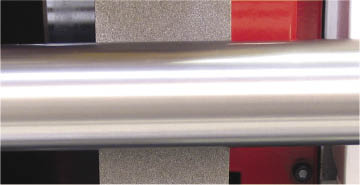

Courtesy of United Grinding

An HVOF-coated aerospace part being ground on a Studer S-33 machine.

Strategies for grinding HVOF-coated aerospace parts.

Chrome may be flashy, but its days in the sun are numbered—including as a coating for aerospace parts.

Engineered hard chrome has been applied to aerospace parts to increase wear resistance and repair or rebuild worn sections. However, the use of hard chrome in aerospace and other applications is being phased out because of environmental and health concerns with hexavalent chrome emissions from the chrome plating process. As a result, high-velocity oxygen-fuel thermal spray coatings are replacing hard chrome on many aerospace parts. HVOF coatings can be used for newly manufactured parts and for repairing worn parts.

With worn parts, machinists typically remove a certain amount of material, eliminating the wear that has developed in the part. They rebuild that surface with HVOF coatings, according to Glen Rosier, applications engineering/business development, Abrasive Technology Inc., Lewis Center, Ohio, a superabrasives manufacturer.

While HVOF coatings were initially targeted as an alternative to hard chrome for health and safety reasons, they have proven to provide better wear and corrosion resistance than hard chrome.

“The environmental reasons are important, but are not as big a driver as everyone thinks,” said Keith O. Legg, a senior analyst at Rowan Technology Group, Libertyville, Ill., a marketing and analysis firm specializing in advanced technologies, materials and coatings. “[Manufacturers] use HVOF coatings because they work better and last longer. With chrome, there are striations after a few years. The chrome becomes worn and damaged. With HVOF coatings, that is not the case.”

A Different Take

The HVOF process is unlike plating, which can coat the entire part. HVOF coatings are deposited in a thermal-spray process where a powdered material is injected into a high-pressure, hot gas stream. The powder is sprayed with a gun onto the part surface and forms a dense, well-adhered coating. HVOF coatings are typically about 0.003 " to 0.005 " thick on original parts, and 0.015 " thick on rebuilt parts because manufacturers are building up the worn area.

The resulting HVOF coating has a hardness of 1,200 to 1,500 HV compared to 800 to 1,000 HV for hard chrome. This makes it highly wear-resistant, but more difficult to grind and otherwise finish.

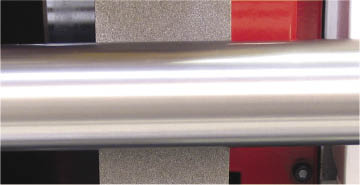

Courtesy of United Grinding

A tungsten-carbide HVOF-coated turbine shaft before (top) and after grinding.

The HVOF coating process can deposit a range of different alloys and cermets. A cermet is a composite material composed of ceramic and metallic materials. The most common alloy coating materials for aerospace applications are tungsten carbide cobalt (WC-Co) and tungsten carbide cobalt chrome (WC-CoCr).

“You typically apply tungsten carbide on moving parts that have surfaces in constant contact,” said Larry Marchand, aerospace account manager, United Grinding Technologies Inc., Miamisburg, Ohio, a grinding machine builder. “You want something extremely hard and that will withstand the constant frictional forces.”

The most common aerospace applications for tungsten-carbide HVOF coatings are landing gear parts, flight control and hydraulic actuators, landing gear and hydraulic system pins, flap and slat tracks and turbine engine shafts. “[The list includes] almost any component subject to wear by rubbing or abrasion, which differs from aircraft to aircraft,” said Legg.

The coated aerospace parts are typically made from HSS, although some titanium parts are HVOF-coated. The use of titanium in aerospace applications is growing because it weighs half as much as steel in similar applications. “And for aircraft, weight is dollars,” said Jon Devereaux, materials and processes engineer, NASA–Kennedy Space Center in Florida. (All opinions expressed by Devereaux in this article are his own and not necessarily those of NASA.)

One limitation with the HVOF coating process, however, is coating deep IDs. With chrome plating, any ID or OD can be coated because a part is immersed in a bath. But the HVOF spray does not reach into deep holes.

“We can coat inner diameters, but it depends on the depth, size and location of these diameters,” said Roger Maragh, process engineer for Hitemco, Old Bethpage, N.Y., which provides coating and grinding services. “After all, this is a line-of-sight process.

The parts themselves are typically from 6 " to 30 " diameter in size, although one company noted it has coated landing gear pins as small as 1.5 " in length with a diameter of less than 0.5 ".

Grinding Approach

Because HVOF coatings are denser and harder than hard chrome, they require a different approach to grind the material to achieve the required finishes and geometries. “The coating has a thick, bumpy surface, so it has to be ground back to the correct geometry or with the proper finish, as far as smoothness and texture,” Marchand said.

A process specification is available—Aerospace Material Specification 2449—for grinding tungsten-carbide HVOF thermal spray coatings applied to HSS for applications requiring wear, heat and corrosion resistance or dimensional restoration. However, usage is not limited to those applications.

NASA’s Devereaux, who sponsored the specification, said, “documenting all aspects of the grinding procedures in some sort of written grinding process control sheet prior to the start of the grinding operation is vital.”

Often, larger and more rigid grinding machines equipped with high-frequency drives are required. Also, minimizing vibration is especially important when grinding HVOF coatings. “Machines with hydrostatic guide ways dampen vibration and offer much smoother grinding with these very hard materials,” Marchand said. “The machine moves on a film of oil and that layer of oil breaks the vibration energy.”

Courtesy of Abrasive Technology

A diamond grinding wheel.

While hard chrome is usually ground with an aluminum-oxide or silicon-carbide grinding wheel, the hardness of HVOF coatings requires that they be ground with a diamond wheel. As a result, the grinding machine requires higher static and dynamic stiffness.

“The diamond wheel itself requires a higher threshold force to make it work,” said Brian Rutkiewicz, manager of applications engineering, Saint-Gobain Abrasives Inc., Worcester, Mass., a manufacturer of high-performance materials, including abrasives. “A wheel that has aluminum-oxide or silicon-carbide abrasives doesn’t need as much force to make it cut.”

Wheel Care

“Because diamond is as hard as it is, diamond wheels can grind substantially higher levels of the coating compared to silicon-carbide and aluminum-oxide wheels,” said Abrasive Technology’s Rosier. “It maintains size and keeps the conformity of the part better.”

The key to grinding HVOF coatings is following correct procedures for diamond wheels, including proper selection of the grinding wheel, grit size, grade and bond type, and proper mounting, balancing, truing and dressing of the wheel prior to grinding, according to NASA’s Devereaux.

Courtesy of CGS

Complete Grinding Solutions uses an acoustic sensor to automatically detect contact between the wheel and the dressing disc.

The first step is properly truing the wheel. “You have to have that wheel running true before you start grinding parts,” said Devereaux. “If you don’t properly true and dress it before you start, you will have problems. You can’t just take a diamond wheel (from the manufacturer) and put it on your grinding machine.”

While most people think a resin-bond diamond wheel should be applied, in many applications vitrified-bond wheels work better. Although these wheels are more expensive, they generally last longer than resin-bond wheels and condition more easily. Also, vitrified-bond diamond wheels can be diamond-dressed on the machine during the grinding process. Resin-bond wheels are typically trued first and then dressed in a secondary manual stick dressing operation.

“Resin-bond diamond wheels traditionally have been used,” said Rutkiewicz. “However, resin- and hybrid-bond technologies have a drawback in that online truing and dressing can be difficult because of the frequency of truing due to form or finish loss and, more importantly, the need to dress or condition (stick-dress) the face after truing. This is because the resin- and hybrid-bond technology has little porosity and, when trued, the abrasive no longer has exposed cutting edges.”

The newest technology employs vitrified-bond diamond wheels. Vitrified wheels are trued and dressed simultaneously with a rotary diamond disk. “With a properly designed truing and dressing diamond rotary-disk dresser and by using the correct parameters, in many applications vitrified wheels may yield the lowest total process cost,” said Rutkiewicz.

For dressing, the grinding machine must be set up for rotary dressing, not with a stationary tool. Stationary diamonds do not have the strength and hardness to efficiently dress vitrified diamond wheels. “A rotary dressing tool is used when dressing a vitrified-bond diamond wheel because there are many more diamonds cutting and it acts like a cutting saw,” said Beat Maurer, president of Complete Grinding Solutions, Springboro, Ohio, which grinds HVOF-coated aerospace parts.

The dressing system must be equipped with a high-frequency drive so it is adjustable in speed and direction to make the wheel cut properly and achieve desired surface finish requirements, according to Maurer. “You can adjust parameters accordingly with the dresser because it is a rotary dresser that can go unidirectional or counterdirectional,” he said. “Unidirectional makes the wheel cut better and counterdirectional provides a better surface finish.”

Maurer added that more sophisticated machines use an acoustic sensor to automatically detect contact between the wheel and the dressing disc so a precisely defined, minimal amount can be dressed.

Other factors to consider are proper application of cutting fluid and selection of feeds and speeds. “For the most part, companies are using emulsion over straight oil due to the cost savings. In general, emulsion is a better coolant but straight oil is a better lubricant,” said Maurer. Diamond wheels are typically run at about 5,000 sfm, according to Maurer.

The coating must be ground without burning the base part, but that is less of an issue with HVOF coatings than chrome. “These coatings are more heat resistant than hard chrome,” Devereaux said. “If you are grinding hard chrome, you definitely have to be careful not to burn the steel underneath it. But we have not seen that with HVOF coatings.”

Superfinishing to the Rescue?

When ordinary grinding does not produce an acceptable surface finish on HVOF-coated aerospace parts, manufacturers turn to superfinishing. “Superfinishing, or microfinishing, is a material-removal application that produces a very smooth, highly uniform surface finish, characterized by a high bearing area, while maintaining or improving part geometry,” said Saint-Gobain’s Rutkiewicz. The superfinished surface is less than 8µin. Ra, typically around 4µin. Ra.

The AMS 2449 specification does not cover superfinishing, but an Aerospace Material Specification for HVOF-applied, tungsten-carbide coatings is expected to be published this year, according to Devereaux.

Courtesy of Clint Forrest, ES-3 Landing Gear Systems

HVOF-coated landing gear components made from titanium.

Superfinishing may not always be required, depending on the application. However, tungsten-carbide coatings have hard, sharp peaks that emerge from the surface, according to Devereaux. “The grinding process (with coarser grit sizes) inherently leaves some of these tungsten-carbide peaks exposed after grinding,” he said. “If not removed or smoothed by the superfinishing process, these particles will damage a mating seal in a hydraulic system, such as landing gear or flight control actuators, which often results in a hydraulic oil leak and premature removal of aircraft components.”

Because of their coarser grit sizes, diamond wheels cannot be used to perform superfinishing. Therefore, diamond belts, stones or paste are used.

While superfinishing of hard chrome is not needed, the benefits of HVOF coatings over hard chrome still are apparent. They provide better wear and corrosion resistance, in addition to environmental benefits. CTE

About the Author: Susan Woods is a contributing editor for CTE. Contact her by e-mail at [email protected].

-------------------------------------------------------------------------------------------------

Courtesy of MesoCoat

PComP powders can replace conventional HVOF coatings using the same application equipment.

Can microcomposite coatings replace HVOF?

Just as hard chrome plating is being replaced by HVOF coating, easier-to-grind microcomposite coatings may replace HVOF coatings, according to one coating supplier. Cermet powders from MesoCoat Inc., Euclid, Ohio, can be used to produce coatings that replace conventional HVOF thermal spray coatings, according to the company. “They are designed to be a drop-in powder replacement for chrome-carbide or tungsten-carbide coatings and can be applied with the same equipment as HVOF coatings,” said Curt Glasgow, general manager, thermal spray for MesoCoat.

Known as PComP, the powders are made with near-nanosize particles of titanium nitride, silicon nitride, tungsten carbide or titanium carbide combined with various metallic binders and sintered to form a hard composite core. The particle core is then further clad with a ductile or tough material, such as nickel or cobalt, forming a core-shell particle.

The coating structure provides a low coefficient of friction and excellent wear and corrosion resistance, according to the company. “The coefficient of friction is orders of magnitude lower than that of tungsten carbide and chrome carbide,” Glasgow said. “The coating is also much more ductile then HVOF wear-resistant coatings. Therefore, it can be built up much thicker, say 0.030 " or 0.040 " thick, and used for repair where thicker buildups are required.”

Also, the nanostructures in the core of the powder provide the coating with a lower modulus of elasticity than standard HVOF coatings. “If you have an application where you have a lot of flexing of the part, such as long hydraulic cylinders or actuators, the lower modulus of elasticity allows it to withstand that flexing much better than tungsten-carbide or chrome-carbide HVOF coatings,” Glasgow said.

Because the hard particles in PComP coatings are nanostructured, anywhere from 80nm to 600nm, the grinding wheel does not cut through them; they are instead removed with the grinding chips. This means that aluminum-oxide or silicon-carbide wheels can be used instead of diamond wheels. “With the larger tungsten-carbide and chrome-carbide particle sizes, when you are grinding you have to cut those hard particles in half so you need a grinding media that is harder than the carbides, such as diamond,” said Glasgow. Also, speeds and feeds typical for hard-chrome grinding can be applied as opposed to the slower feeds needed for carbides.

PComP coatings can be ground to finishes as fine as 8µin. Ra with conventional grinding wheels. “You don’t have to superfinish it to get the desired surface characteristics,” Glasgow noted. “The coating is like hard chrome in that you can produce a 10µin. Ra finish directly from grinding. If you have an application on hard chrome that requires 16µin. Ra, if you were going to replace that with a tungsten-carbide coating and get an equivalent surface, you’d probably have to be at 6µin. Ra or 8µin. Ra. You’d have to grind that and superfinish it to get the surface equivalent of the hard chrome.”

PComP can be used for wear coatings on aircraft parts, including landing gear and actuators. It can also be used for dimensional part restoration. “We are going through the approval process with various customers in the defense and commercial aerospace markets,” Glasgow said. “We have development partnerships with the Air Force and others. We should have acceptance from customers in the next 3 or 4 months.”

—S. Woods

------------------------------------------------------------------------------------

Contributors

Abrasive Technology Inc.

(740) 548-4100

Diamond grinding wheels, CBN grinding wheels, wear parts and PCD tooling from Abrasive Technology

Complete Grinding Solutions

(937) 746-7888

Complete Grinding Solutions

Hitemco

(516) 752-7882

Hitemco

MesoCoat Inc.

(216) 453-0866

MesoCoat Inc

Rowan Technology Group

(847) 680-9420

Rowan Technology Group - Title -

Saint-Gobain Abrasives Inc.

(866) 279-3520

Norton Abrasives Products | North America

United Grinding Technologies Inc.

(937) 859-1975

Grinding.com: Your #1 Source for CNC Grinding Solutions - Grinding.com

Click Here for a free subscription to Cutting Tool Engineering magazine.

*This article is reprinted with permission from CUTTING TOOL ENGINEERING Magazine, and is protected under U.S. and international copyright laws. CUTTING TOOL ENGINEERING Magazine is protected under U.S. and international copyright laws. Before reproducing anything from this Web site, call the Copyright Clearance Center Inc. at (978) 750-8400.

Click Here for a free subscription to Cutting Tool Engineering magazine.

Courtesy of United Grinding

An HVOF-coated aerospace part being ground on a Studer S-33 machine.

Strategies for grinding HVOF-coated aerospace parts.

Chrome may be flashy, but its days in the sun are numbered—including as a coating for aerospace parts.

Engineered hard chrome has been applied to aerospace parts to increase wear resistance and repair or rebuild worn sections. However, the use of hard chrome in aerospace and other applications is being phased out because of environmental and health concerns with hexavalent chrome emissions from the chrome plating process. As a result, high-velocity oxygen-fuel thermal spray coatings are replacing hard chrome on many aerospace parts. HVOF coatings can be used for newly manufactured parts and for repairing worn parts.

With worn parts, machinists typically remove a certain amount of material, eliminating the wear that has developed in the part. They rebuild that surface with HVOF coatings, according to Glen Rosier, applications engineering/business development, Abrasive Technology Inc., Lewis Center, Ohio, a superabrasives manufacturer.

While HVOF coatings were initially targeted as an alternative to hard chrome for health and safety reasons, they have proven to provide better wear and corrosion resistance than hard chrome.

“The environmental reasons are important, but are not as big a driver as everyone thinks,” said Keith O. Legg, a senior analyst at Rowan Technology Group, Libertyville, Ill., a marketing and analysis firm specializing in advanced technologies, materials and coatings. “[Manufacturers] use HVOF coatings because they work better and last longer. With chrome, there are striations after a few years. The chrome becomes worn and damaged. With HVOF coatings, that is not the case.”

A Different Take

The HVOF process is unlike plating, which can coat the entire part. HVOF coatings are deposited in a thermal-spray process where a powdered material is injected into a high-pressure, hot gas stream. The powder is sprayed with a gun onto the part surface and forms a dense, well-adhered coating. HVOF coatings are typically about 0.003 " to 0.005 " thick on original parts, and 0.015 " thick on rebuilt parts because manufacturers are building up the worn area.

The resulting HVOF coating has a hardness of 1,200 to 1,500 HV compared to 800 to 1,000 HV for hard chrome. This makes it highly wear-resistant, but more difficult to grind and otherwise finish.

Courtesy of United Grinding

A tungsten-carbide HVOF-coated turbine shaft before (top) and after grinding.

The HVOF coating process can deposit a range of different alloys and cermets. A cermet is a composite material composed of ceramic and metallic materials. The most common alloy coating materials for aerospace applications are tungsten carbide cobalt (WC-Co) and tungsten carbide cobalt chrome (WC-CoCr).

“You typically apply tungsten carbide on moving parts that have surfaces in constant contact,” said Larry Marchand, aerospace account manager, United Grinding Technologies Inc., Miamisburg, Ohio, a grinding machine builder. “You want something extremely hard and that will withstand the constant frictional forces.”

The most common aerospace applications for tungsten-carbide HVOF coatings are landing gear parts, flight control and hydraulic actuators, landing gear and hydraulic system pins, flap and slat tracks and turbine engine shafts. “[The list includes] almost any component subject to wear by rubbing or abrasion, which differs from aircraft to aircraft,” said Legg.

The coated aerospace parts are typically made from HSS, although some titanium parts are HVOF-coated. The use of titanium in aerospace applications is growing because it weighs half as much as steel in similar applications. “And for aircraft, weight is dollars,” said Jon Devereaux, materials and processes engineer, NASA–Kennedy Space Center in Florida. (All opinions expressed by Devereaux in this article are his own and not necessarily those of NASA.)

One limitation with the HVOF coating process, however, is coating deep IDs. With chrome plating, any ID or OD can be coated because a part is immersed in a bath. But the HVOF spray does not reach into deep holes.

“We can coat inner diameters, but it depends on the depth, size and location of these diameters,” said Roger Maragh, process engineer for Hitemco, Old Bethpage, N.Y., which provides coating and grinding services. “After all, this is a line-of-sight process.

The parts themselves are typically from 6 " to 30 " diameter in size, although one company noted it has coated landing gear pins as small as 1.5 " in length with a diameter of less than 0.5 ".

Grinding Approach

Because HVOF coatings are denser and harder than hard chrome, they require a different approach to grind the material to achieve the required finishes and geometries. “The coating has a thick, bumpy surface, so it has to be ground back to the correct geometry or with the proper finish, as far as smoothness and texture,” Marchand said.

A process specification is available—Aerospace Material Specification 2449—for grinding tungsten-carbide HVOF thermal spray coatings applied to HSS for applications requiring wear, heat and corrosion resistance or dimensional restoration. However, usage is not limited to those applications.

NASA’s Devereaux, who sponsored the specification, said, “documenting all aspects of the grinding procedures in some sort of written grinding process control sheet prior to the start of the grinding operation is vital.”

Often, larger and more rigid grinding machines equipped with high-frequency drives are required. Also, minimizing vibration is especially important when grinding HVOF coatings. “Machines with hydrostatic guide ways dampen vibration and offer much smoother grinding with these very hard materials,” Marchand said. “The machine moves on a film of oil and that layer of oil breaks the vibration energy.”

Courtesy of Abrasive Technology

A diamond grinding wheel.

While hard chrome is usually ground with an aluminum-oxide or silicon-carbide grinding wheel, the hardness of HVOF coatings requires that they be ground with a diamond wheel. As a result, the grinding machine requires higher static and dynamic stiffness.

“The diamond wheel itself requires a higher threshold force to make it work,” said Brian Rutkiewicz, manager of applications engineering, Saint-Gobain Abrasives Inc., Worcester, Mass., a manufacturer of high-performance materials, including abrasives. “A wheel that has aluminum-oxide or silicon-carbide abrasives doesn’t need as much force to make it cut.”

Wheel Care

“Because diamond is as hard as it is, diamond wheels can grind substantially higher levels of the coating compared to silicon-carbide and aluminum-oxide wheels,” said Abrasive Technology’s Rosier. “It maintains size and keeps the conformity of the part better.”

The key to grinding HVOF coatings is following correct procedures for diamond wheels, including proper selection of the grinding wheel, grit size, grade and bond type, and proper mounting, balancing, truing and dressing of the wheel prior to grinding, according to NASA’s Devereaux.

Courtesy of CGS

Complete Grinding Solutions uses an acoustic sensor to automatically detect contact between the wheel and the dressing disc.

The first step is properly truing the wheel. “You have to have that wheel running true before you start grinding parts,” said Devereaux. “If you don’t properly true and dress it before you start, you will have problems. You can’t just take a diamond wheel (from the manufacturer) and put it on your grinding machine.”

While most people think a resin-bond diamond wheel should be applied, in many applications vitrified-bond wheels work better. Although these wheels are more expensive, they generally last longer than resin-bond wheels and condition more easily. Also, vitrified-bond diamond wheels can be diamond-dressed on the machine during the grinding process. Resin-bond wheels are typically trued first and then dressed in a secondary manual stick dressing operation.

“Resin-bond diamond wheels traditionally have been used,” said Rutkiewicz. “However, resin- and hybrid-bond technologies have a drawback in that online truing and dressing can be difficult because of the frequency of truing due to form or finish loss and, more importantly, the need to dress or condition (stick-dress) the face after truing. This is because the resin- and hybrid-bond technology has little porosity and, when trued, the abrasive no longer has exposed cutting edges.”

The newest technology employs vitrified-bond diamond wheels. Vitrified wheels are trued and dressed simultaneously with a rotary diamond disk. “With a properly designed truing and dressing diamond rotary-disk dresser and by using the correct parameters, in many applications vitrified wheels may yield the lowest total process cost,” said Rutkiewicz.

For dressing, the grinding machine must be set up for rotary dressing, not with a stationary tool. Stationary diamonds do not have the strength and hardness to efficiently dress vitrified diamond wheels. “A rotary dressing tool is used when dressing a vitrified-bond diamond wheel because there are many more diamonds cutting and it acts like a cutting saw,” said Beat Maurer, president of Complete Grinding Solutions, Springboro, Ohio, which grinds HVOF-coated aerospace parts.

The dressing system must be equipped with a high-frequency drive so it is adjustable in speed and direction to make the wheel cut properly and achieve desired surface finish requirements, according to Maurer. “You can adjust parameters accordingly with the dresser because it is a rotary dresser that can go unidirectional or counterdirectional,” he said. “Unidirectional makes the wheel cut better and counterdirectional provides a better surface finish.”

Maurer added that more sophisticated machines use an acoustic sensor to automatically detect contact between the wheel and the dressing disc so a precisely defined, minimal amount can be dressed.

Other factors to consider are proper application of cutting fluid and selection of feeds and speeds. “For the most part, companies are using emulsion over straight oil due to the cost savings. In general, emulsion is a better coolant but straight oil is a better lubricant,” said Maurer. Diamond wheels are typically run at about 5,000 sfm, according to Maurer.

The coating must be ground without burning the base part, but that is less of an issue with HVOF coatings than chrome. “These coatings are more heat resistant than hard chrome,” Devereaux said. “If you are grinding hard chrome, you definitely have to be careful not to burn the steel underneath it. But we have not seen that with HVOF coatings.”

Superfinishing to the Rescue?

When ordinary grinding does not produce an acceptable surface finish on HVOF-coated aerospace parts, manufacturers turn to superfinishing. “Superfinishing, or microfinishing, is a material-removal application that produces a very smooth, highly uniform surface finish, characterized by a high bearing area, while maintaining or improving part geometry,” said Saint-Gobain’s Rutkiewicz. The superfinished surface is less than 8µin. Ra, typically around 4µin. Ra.

The AMS 2449 specification does not cover superfinishing, but an Aerospace Material Specification for HVOF-applied, tungsten-carbide coatings is expected to be published this year, according to Devereaux.

Courtesy of Clint Forrest, ES-3 Landing Gear Systems

HVOF-coated landing gear components made from titanium.

Superfinishing may not always be required, depending on the application. However, tungsten-carbide coatings have hard, sharp peaks that emerge from the surface, according to Devereaux. “The grinding process (with coarser grit sizes) inherently leaves some of these tungsten-carbide peaks exposed after grinding,” he said. “If not removed or smoothed by the superfinishing process, these particles will damage a mating seal in a hydraulic system, such as landing gear or flight control actuators, which often results in a hydraulic oil leak and premature removal of aircraft components.”

Because of their coarser grit sizes, diamond wheels cannot be used to perform superfinishing. Therefore, diamond belts, stones or paste are used.

While superfinishing of hard chrome is not needed, the benefits of HVOF coatings over hard chrome still are apparent. They provide better wear and corrosion resistance, in addition to environmental benefits. CTE

About the Author: Susan Woods is a contributing editor for CTE. Contact her by e-mail at [email protected].

-------------------------------------------------------------------------------------------------

Courtesy of MesoCoat

PComP powders can replace conventional HVOF coatings using the same application equipment.

Can microcomposite coatings replace HVOF?

Just as hard chrome plating is being replaced by HVOF coating, easier-to-grind microcomposite coatings may replace HVOF coatings, according to one coating supplier. Cermet powders from MesoCoat Inc., Euclid, Ohio, can be used to produce coatings that replace conventional HVOF thermal spray coatings, according to the company. “They are designed to be a drop-in powder replacement for chrome-carbide or tungsten-carbide coatings and can be applied with the same equipment as HVOF coatings,” said Curt Glasgow, general manager, thermal spray for MesoCoat.

Known as PComP, the powders are made with near-nanosize particles of titanium nitride, silicon nitride, tungsten carbide or titanium carbide combined with various metallic binders and sintered to form a hard composite core. The particle core is then further clad with a ductile or tough material, such as nickel or cobalt, forming a core-shell particle.

The coating structure provides a low coefficient of friction and excellent wear and corrosion resistance, according to the company. “The coefficient of friction is orders of magnitude lower than that of tungsten carbide and chrome carbide,” Glasgow said. “The coating is also much more ductile then HVOF wear-resistant coatings. Therefore, it can be built up much thicker, say 0.030 " or 0.040 " thick, and used for repair where thicker buildups are required.”

Also, the nanostructures in the core of the powder provide the coating with a lower modulus of elasticity than standard HVOF coatings. “If you have an application where you have a lot of flexing of the part, such as long hydraulic cylinders or actuators, the lower modulus of elasticity allows it to withstand that flexing much better than tungsten-carbide or chrome-carbide HVOF coatings,” Glasgow said.

Because the hard particles in PComP coatings are nanostructured, anywhere from 80nm to 600nm, the grinding wheel does not cut through them; they are instead removed with the grinding chips. This means that aluminum-oxide or silicon-carbide wheels can be used instead of diamond wheels. “With the larger tungsten-carbide and chrome-carbide particle sizes, when you are grinding you have to cut those hard particles in half so you need a grinding media that is harder than the carbides, such as diamond,” said Glasgow. Also, speeds and feeds typical for hard-chrome grinding can be applied as opposed to the slower feeds needed for carbides.

PComP coatings can be ground to finishes as fine as 8µin. Ra with conventional grinding wheels. “You don’t have to superfinish it to get the desired surface characteristics,” Glasgow noted. “The coating is like hard chrome in that you can produce a 10µin. Ra finish directly from grinding. If you have an application on hard chrome that requires 16µin. Ra, if you were going to replace that with a tungsten-carbide coating and get an equivalent surface, you’d probably have to be at 6µin. Ra or 8µin. Ra. You’d have to grind that and superfinish it to get the surface equivalent of the hard chrome.”

PComP can be used for wear coatings on aircraft parts, including landing gear and actuators. It can also be used for dimensional part restoration. “We are going through the approval process with various customers in the defense and commercial aerospace markets,” Glasgow said. “We have development partnerships with the Air Force and others. We should have acceptance from customers in the next 3 or 4 months.”

—S. Woods

------------------------------------------------------------------------------------

Contributors

Abrasive Technology Inc.

(740) 548-4100

Diamond grinding wheels, CBN grinding wheels, wear parts and PCD tooling from Abrasive Technology

Complete Grinding Solutions

(937) 746-7888

Complete Grinding Solutions

Hitemco

(516) 752-7882

Hitemco

MesoCoat Inc.

(216) 453-0866

MesoCoat Inc

Rowan Technology Group

(847) 680-9420

Rowan Technology Group - Title -

Saint-Gobain Abrasives Inc.

(866) 279-3520

Norton Abrasives Products | North America

United Grinding Technologies Inc.

(937) 859-1975

Grinding.com: Your #1 Source for CNC Grinding Solutions - Grinding.com

Click Here for a free subscription to Cutting Tool Engineering magazine.

*This article is reprinted with permission from CUTTING TOOL ENGINEERING Magazine, and is protected under U.S. and international copyright laws. CUTTING TOOL ENGINEERING Magazine is protected under U.S. and international copyright laws. Before reproducing anything from this Web site, call the Copyright Clearance Center Inc. at (978) 750-8400.