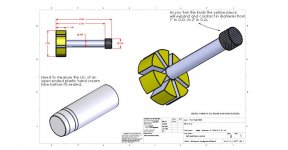

Okay I am looking for a tool like what I have drawn up in my attached photo. Does anybody make a tool like this already or know where I could have one made, etc.?

I need to measure the I.D. of plastic tubes used in say hand creams, toothpaste, etc. before the tubes are sealed closed. As we all know these tubes are very flexible plastic so holding them in round perfectly is not very easy. And for any tube sizes bigger than 1" in I.D. I do NOT have PIN gages that big.. my pin gages only go up to 1" in O.D.

Thanks all!

I need to measure the I.D. of plastic tubes used in say hand creams, toothpaste, etc. before the tubes are sealed closed. As we all know these tubes are very flexible plastic so holding them in round perfectly is not very easy. And for any tube sizes bigger than 1" in I.D. I do NOT have PIN gages that big.. my pin gages only go up to 1" in O.D.

Thanks all!