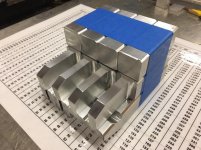

I'm a garage level machine shop with a cnc lathe and Bridgeport. I'm machining rectangular fittings 1x1x5 inch major dimensions and I've been asked to tumble deburr for aesthetics. Is there a general rule how big a tumbler must be relative to the parts in work? I've heard that parts will bind against each other and be damaged when they're too big for the bin. Is this also a concern with a rotary tumbler?

I have two default bargain options in mind:

1. Northern Tool 1.25 cft tumbler for $850

2. 6" or 8" pvc container to spin on my 10" Logan 825 lathe

I don't have the operating cash to spend more than $1000 on a tumbler right now. I have money on paper, but not until I get repaid on materials and work...

Any recommendation what media to get for said tumbler options above? 6061-T6 rectangular fittings to be tumbled. The main goals are smooth aesthetic appearance, deburr edges, and not to cause stress riser features.

Thanks in advance,

Kevin

I have two default bargain options in mind:

1. Northern Tool 1.25 cft tumbler for $850

2. 6" or 8" pvc container to spin on my 10" Logan 825 lathe

I don't have the operating cash to spend more than $1000 on a tumbler right now. I have money on paper, but not until I get repaid on materials and work...

Any recommendation what media to get for said tumbler options above? 6061-T6 rectangular fittings to be tumbled. The main goals are smooth aesthetic appearance, deburr edges, and not to cause stress riser features.

Thanks in advance,

Kevin