I am using a G71 roughing cycle with a boring bar. After making the rough pass, I would like it to retract along Z without any X movement. The Fanuc manuals don't mention anything about this behavior and I can't find a parameter related to it. Control is an Oi-TF Plus

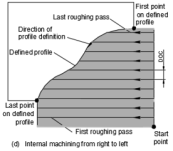

(Error: The note in the picture is wrong. It's retracting to the start of the pass it just finished, not "next pass")

(Error: The note in the picture is wrong. It's retracting to the start of the pass it just finished, not "next pass")

Last edited: