metalcage

Plastic

- Joined

- Apr 17, 2024

- Location

- United States

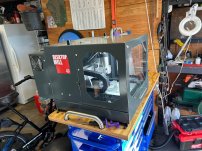

The Haas Desktop Mill is the ultimate training machine for schools and technical colleges. Powered by a full-function Haas CNC control housed in our portable simulator enclosure, the Desktop Mill is perfect for teaching the basic principles of programming and operating a CNC mill. Designed to cut plastics and machinable wax, it is also perfect for hobbyists and benchtop machinists.

Portable design easily fits onto a desktop or rolling toolbox

Powered by a full-function Haas control

15,000-rpm electric spindle

Ethernet and WiFi connectivity

M130 Media Display M-code

price: $4500

Portable design easily fits onto a desktop or rolling toolbox

Powered by a full-function Haas control

15,000-rpm electric spindle

Ethernet and WiFi connectivity

M130 Media Display M-code

price: $4500