Frank_Dorion

Aluminum

- Joined

- Aug 4, 2004

- Location

- Plainville, CT USA

I’m posting this as a new item because it’s essentially a different question from the inquiry I just made about the metric transposing plate.

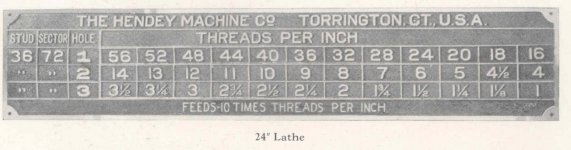

John Oder was kind enough to post a nice legible version of the plate in question. With that information in hand, my friend and I got out the new metric transposing gears he had made and began to set up for cutting a metric thread on his Hendey 24” gearhead with a 2 TPI leadscrew. Big problem! When the 127 tooth gear (Gear C) is mounted on the banjo, it interferes with the gear box housing before the adjacent gear (Gear E) is even close to meshing with Gear F. [See attached diagram] We fooled with the banjo for a while looking for a way to make this gear combination work, but were forced to conclude that there is no way to complete the gear train because the 127 tooth gear is just too large to allow Gear E and Gear F to mesh.

So, we threw in the towel for the moment and I was on my way out the door when I remembered that the metric transposing gears on my Monarch 10EE are a smaller pitch than the rest of the gear train so a 127 tooth gear can be squeezed into a relatively small space. Is that what’s going on with the Hendey? Are my friend's transposing gears the wrong DP? Anybody have a set of metric transposing gears for a big gearhead Hendey that can tell us what pitch those gears are, or at least whether or not the transposing gears are a smaller pitch than the rest of the gear train? Any help would be much appreciated. Thanks.

Frank

John Oder was kind enough to post a nice legible version of the plate in question. With that information in hand, my friend and I got out the new metric transposing gears he had made and began to set up for cutting a metric thread on his Hendey 24” gearhead with a 2 TPI leadscrew. Big problem! When the 127 tooth gear (Gear C) is mounted on the banjo, it interferes with the gear box housing before the adjacent gear (Gear E) is even close to meshing with Gear F. [See attached diagram] We fooled with the banjo for a while looking for a way to make this gear combination work, but were forced to conclude that there is no way to complete the gear train because the 127 tooth gear is just too large to allow Gear E and Gear F to mesh.

So, we threw in the towel for the moment and I was on my way out the door when I remembered that the metric transposing gears on my Monarch 10EE are a smaller pitch than the rest of the gear train so a 127 tooth gear can be squeezed into a relatively small space. Is that what’s going on with the Hendey? Are my friend's transposing gears the wrong DP? Anybody have a set of metric transposing gears for a big gearhead Hendey that can tell us what pitch those gears are, or at least whether or not the transposing gears are a smaller pitch than the rest of the gear train? Any help would be much appreciated. Thanks.

Frank