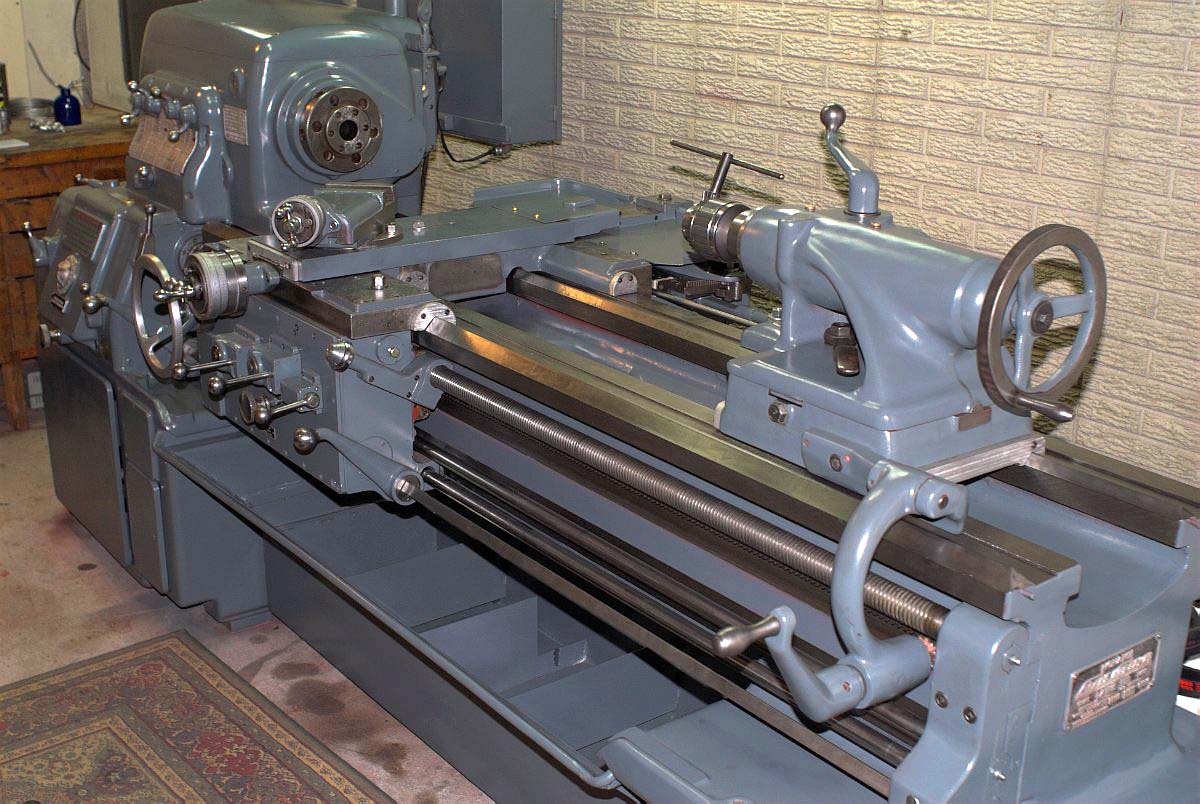

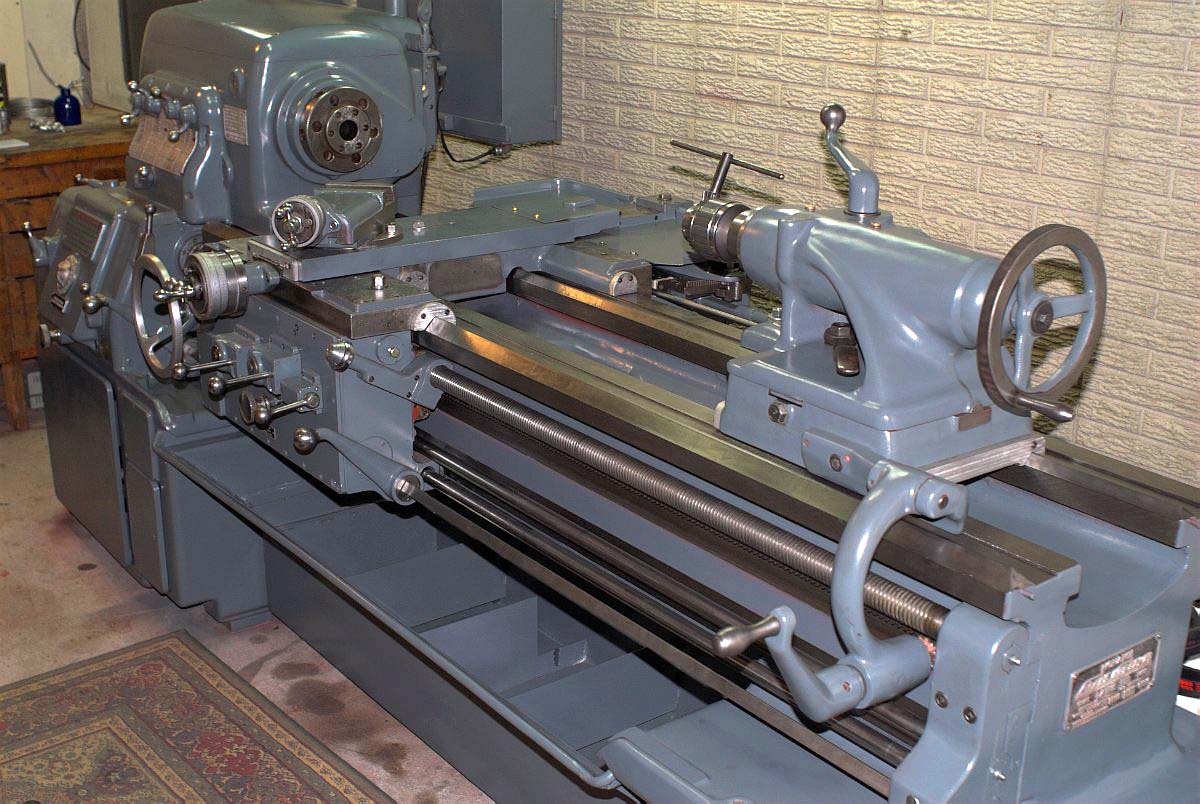

ions82, It is a Persian Rug... Nothing but the best for the shop!

Actually my wife donates these rugs after she decides they are too worn out for the house.

I've been on the project since January. Evenings and weekends.

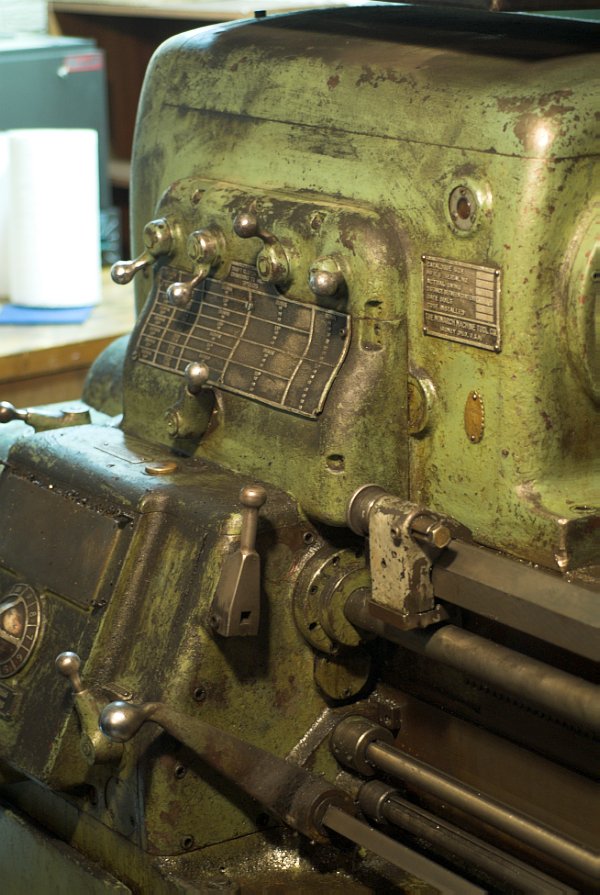

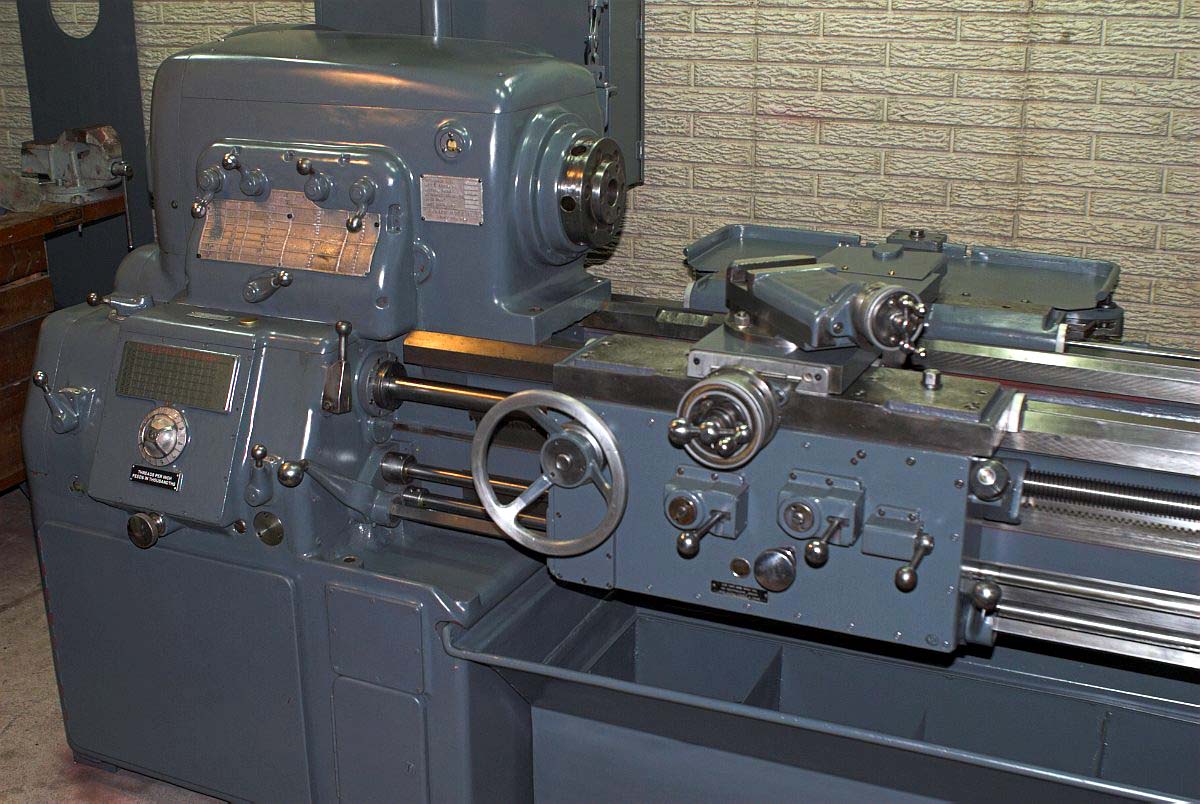

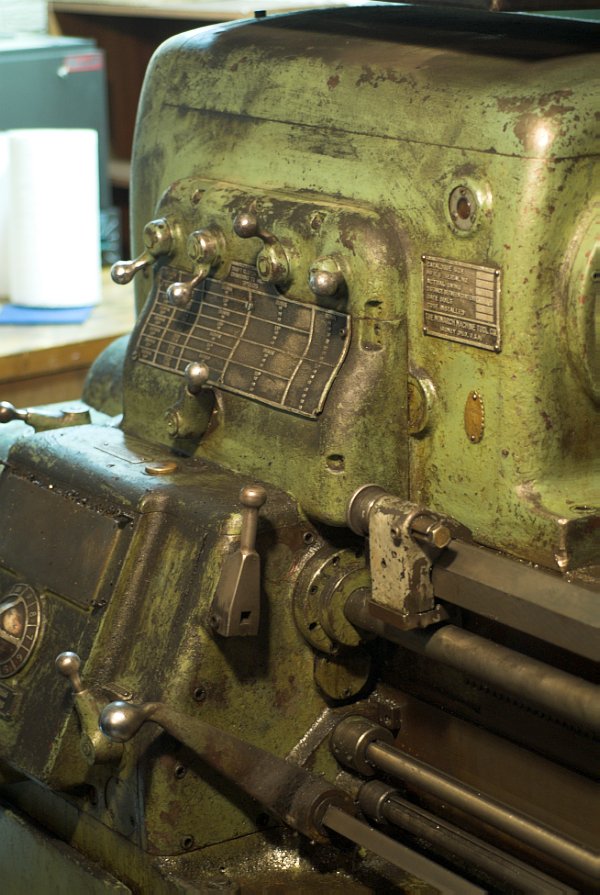

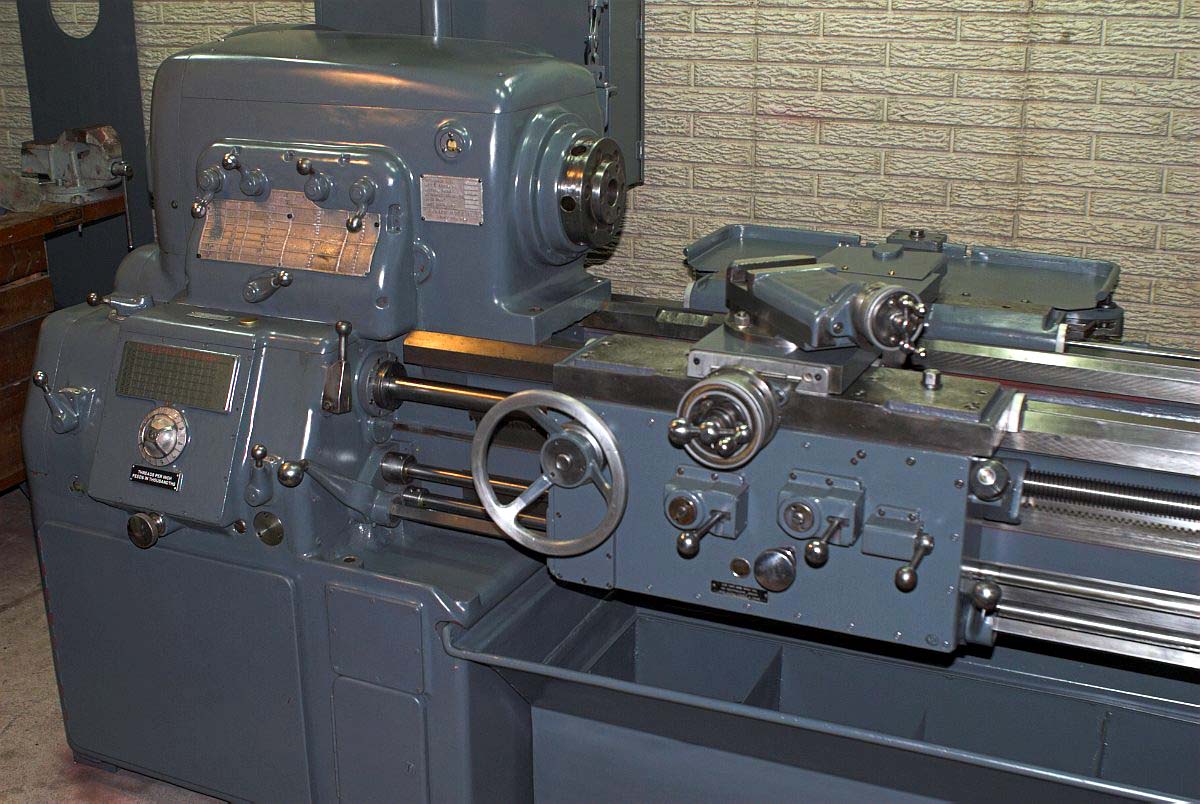

The bottom of carriage had turcite on it already. This probably saved the bed because the oiling system was plugged up. I glued .015" thick turcite to the bottom of the cross feed slide and scraped it using a surface plate. Then used it to fit to the mating slide on the carriage. The dovetail on the left side of the slide was worn with a bow. Got it scraped out straight and had to add another .010" shim to the gib along with the .015" high turcite.

Rapid transverse gears were worn and had new gears made for that. Bearings in the clutch were bad, also replaced all the bearings in the taper attachment. Replaced the restrictor oil valves in the carriage, gearbox and head. There was one between the gearbox and head that was challenging to replace. Found a time clock factory ticket used as a shim in the carriage. It had a date of 1983 written it. So I assume this was the last time it was gone through and the turcite was added to the bottom of the carriage.

The bed bracket for the taper attachment was missing. Ordered one from Monarch for $695.

It was in stock, so it must be one of the usual missing items people order.

Also the threading dial bracket was missing, $1223 for that.

The engraved metal index plate was also missing, $451

The parts may be expensive from Monarch but they are first rate quality. The service, people and parts at Monarch are super! Thank you Monarch!

Cal, I used bondo lacquer spot putty for filler. Probably 50 tubes to fill the rough castings. Paint is from a can. Maybe 15 cans of primer and 25 cans of paint. Krylon #1611 Universal Gray Engine Paint. It is a little more of a darker blue grey compared to other grey machine paints I can find in a can. I've decided it easier using can paint simply because it is so easy to repair. I keep extra around along with the spot putty, and it is fast to repair damaged paint.