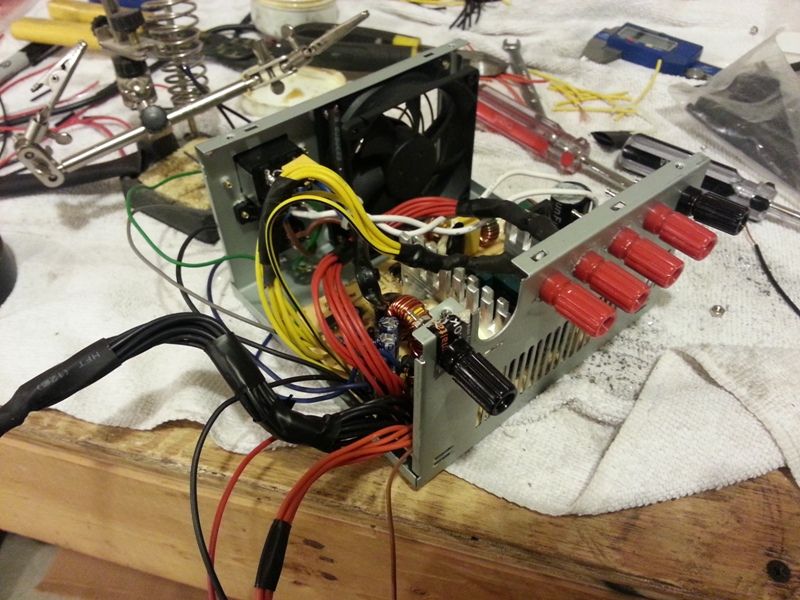

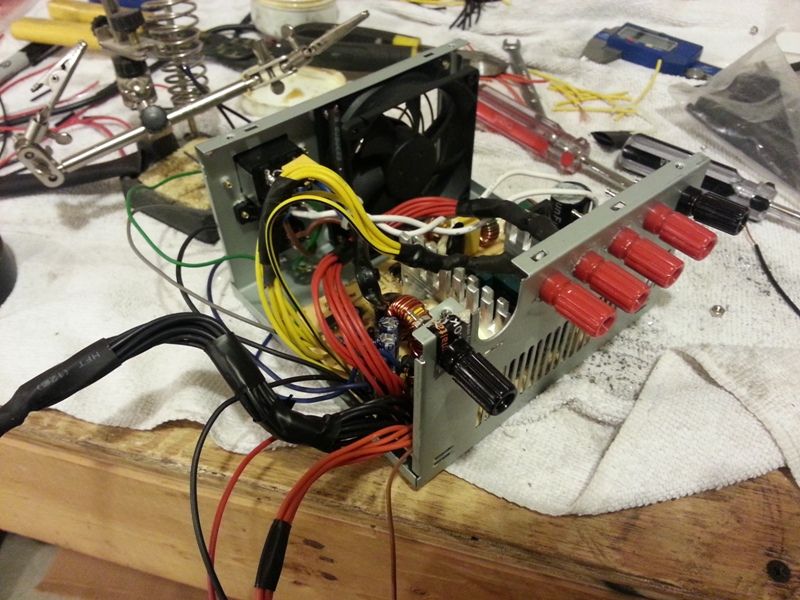

Found instructions on how to convert a computer power supply to a lab power supply: How to Convert a Computer ATX Power Supply to a Lab Power Supply

I wanted to try electrolysis and had a couple laying around so I made one. There's a lot of wires but all in all it was pretty easy.

I will get some after pics. I purchased graphite rod as others have mentioned. I have only done it on the cabinet doors and sides so far but it does get the paint off. You do need to brush it quick once and then it does the rest. Its not perfect but it, and I could definitely improve upon my method by using more graphite as I only have 1 right now, but it sure beats doing everything by hand. I put it in the tank and come back a day later. Allows me to get other stuff done.

I wanted to try electrolysis and had a couple laying around so I made one. There's a lot of wires but all in all it was pretty easy.

I will get some after pics. I purchased graphite rod as others have mentioned. I have only done it on the cabinet doors and sides so far but it does get the paint off. You do need to brush it quick once and then it does the rest. Its not perfect but it, and I could definitely improve upon my method by using more graphite as I only have 1 right now, but it sure beats doing everything by hand. I put it in the tank and come back a day later. Allows me to get other stuff done.