skipd1

Cast Iron

- Joined

- Jan 6, 2010

- Location

- Bismarck, ND

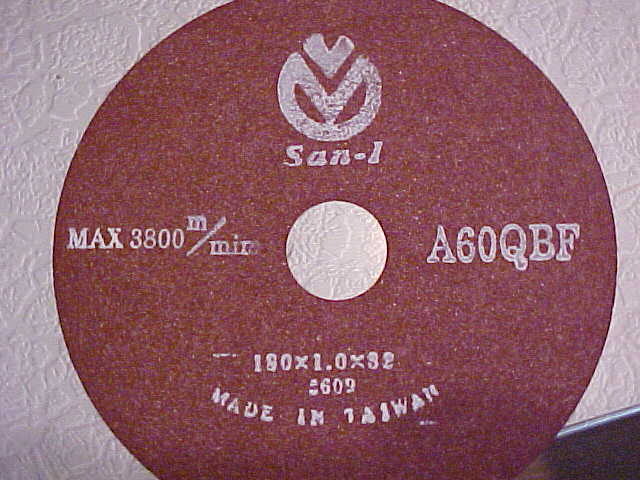

I added some abrasive cut-off wheels to my order of Norton wheels. I have a .062 A60 and .062 A46 PBC cut-off wheels. I noticed none of my adapters tighten down enough to hold these wheels. What kind of wheel adapter do I need to mount these cut-off wheels on my Harig 612 grinder?

Thanks

Skipd1

Thanks

Skipd1

. probably any material from steel, brass, Delrin/acetal etc. will do the job.

. probably any material from steel, brass, Delrin/acetal etc. will do the job.