StrayAlien

Cast Iron

- Joined

- Aug 18, 2014

- Location

- Melbourne, Australia

Hi all,

I recently acquired a complete basket case Brown and Sharpe No2 surface grinder SN #8138 - which as far as I can tell is 1928. Apologies for the other-forum link post but I really need all the help I can get on this one. She really is in a terrible terrible state. From a deceased estate it was dismantled about 10 years ago and then all parts except the body and table were put outside in boxes .. in the rain and weather.

Some more info on this thread:

http://metalworkforums.com/f65/t199759-brown-sharpe-2-surface-grinder-basket

But some photos to show the scale of the 'challenge':

I didn't actually see the carriage at first but I kicked something accidentally and there it was under a layer of grass.

The rest lived inside the barn and is in better condition. Tired, but better.

With electrolysis and a good WD40 soak everything is cleaning up and seized assemblies are coming apart. Some of it in atrocious condition, others better than you think possible. Quite some stuff will need to be remade. But, to be honest, it is looking better than it (erm) looks.

Before you all call me crazy, this is a learning experience for me. It cost me nothing and I'll learn a lot of stuff and hopefully get a grinder out of it - I have never used a grinder before. I was looking for one to learn on to make restore some gibs and other small pieces, so my questions may be a little on the naive side. Apologies.

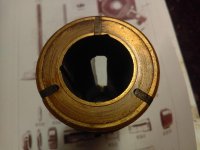

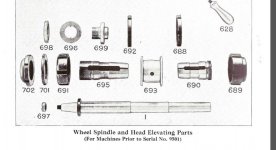

You'll notice the spindle in the first photo above - it is 'no more pining for the fjords'. An ex-spindle. It is plain bearing spindle, but the early type. No taper, no ball/roller bearings - just a straight shaft. From the 1936 parts list it is this:

but now looks like this:

![IMAG0379[1].jpg IMAG0379[1].jpg](https://www.practicalmachinist.com/forum/data/attachments/153/153125-6552926d37db6888cd5f6f7594da0fbd.jpg)

Toast. So some questions if I may. All help appreciated.

I'll need to get one made, make one, find one in an attic or something. So, anybody got one? :-) or a lead to start finding one?

If it comes to getting one made (and having the bearing 'boxes' done to match) any ideas what kind of clearance this guy has on the spindle boxes? The operator manual says 0.00011" but all indications are that is for the later taper type. Same?

Again, all help appreciated, and apologies for the link post, but, I'd like to get this old girl working again. It makes me sad to see old machinery go to scrap and that is where she was going. But she ain't going to work without a spindle so I am trying all avenues.

Greg.

I recently acquired a complete basket case Brown and Sharpe No2 surface grinder SN #8138 - which as far as I can tell is 1928. Apologies for the other-forum link post but I really need all the help I can get on this one. She really is in a terrible terrible state. From a deceased estate it was dismantled about 10 years ago and then all parts except the body and table were put outside in boxes .. in the rain and weather.

Some more info on this thread:

http://metalworkforums.com/f65/t199759-brown-sharpe-2-surface-grinder-basket

But some photos to show the scale of the 'challenge':

I didn't actually see the carriage at first but I kicked something accidentally and there it was under a layer of grass.

The rest lived inside the barn and is in better condition. Tired, but better.

With electrolysis and a good WD40 soak everything is cleaning up and seized assemblies are coming apart. Some of it in atrocious condition, others better than you think possible. Quite some stuff will need to be remade. But, to be honest, it is looking better than it (erm) looks.

Before you all call me crazy, this is a learning experience for me. It cost me nothing and I'll learn a lot of stuff and hopefully get a grinder out of it - I have never used a grinder before. I was looking for one to learn on to make restore some gibs and other small pieces, so my questions may be a little on the naive side. Apologies.

You'll notice the spindle in the first photo above - it is 'no more pining for the fjords'. An ex-spindle. It is plain bearing spindle, but the early type. No taper, no ball/roller bearings - just a straight shaft. From the 1936 parts list it is this:

but now looks like this:

![IMAG0379[1].jpg IMAG0379[1].jpg](https://www.practicalmachinist.com/forum/data/attachments/153/153125-6552926d37db6888cd5f6f7594da0fbd.jpg)

Toast. So some questions if I may. All help appreciated.

I'll need to get one made, make one, find one in an attic or something. So, anybody got one? :-) or a lead to start finding one?

If it comes to getting one made (and having the bearing 'boxes' done to match) any ideas what kind of clearance this guy has on the spindle boxes? The operator manual says 0.00011" but all indications are that is for the later taper type. Same?

Again, all help appreciated, and apologies for the link post, but, I'd like to get this old girl working again. It makes me sad to see old machinery go to scrap and that is where she was going. But she ain't going to work without a spindle so I am trying all avenues.

Greg.