L Vanice

Diamond

- Joined

- Feb 8, 2006

- Location

- Fort Wayne, IN

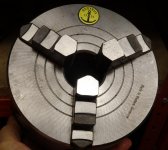

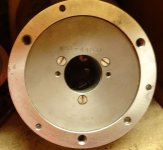

By popular demand (sorta), I am starting a thread to examine combination lathe chucks with jaws that are both universal (all move together when the key is turned) and independent (each jaw is moved separately).

The oldest chucks of this type that I have seen were invented by John H. Westcott of Oneida, NY in the late 19th century. I have seen a few of these, but never bought one. They looked more like museum pieces than something I would actually use and most were too big for my lathes. I never saw one of those chucks that still had the special wrenches with it. Westcott did not use a pinion gear to rotate the ring gear or scroll. The back of the ring gear or scroll had some blind holes and you needed a special wrench to adjust it.

Here is a Westcott company history:

Westcott Chuck Co. - History | VintageMachinery.org

And here is a list of Westcott patents:

Westcott Chuck Co. - Assigned Patents | VintageMachinery.org

Here is the 1873 Westcott combination chuck patent:

Patent Images

I have a couple of Skinner combination chucks, so Westcott did have competition in this area. To get their patent, of course Skinner had to find a completely different way of getting the same result as Westcott. I am not happy with the way the Skinner chucks operate, but they are about 100 years old, so maybe they were nicer when new. You can recognize one by the sliding knurled nut on the back of the chuck. They use a female square key. I have not researched all the Skinner patents, but I do know that Skinner was awarded two patents for two-piece reversible chuck jaws in 1891. I don't know if that was the first such jaw design for a heavy duty chuck. But American Watch Tool Co. had a watch lathe 3-jaw chuck design with 1881 patent dates that had two-piece non-reversible jaws.

Here is a Skinner ad from 1912 for their combination chuck that shows their patented jaw design:

Skinner Chuck Co. - 1912 ad - Skinner combination chucks | VintageMachinery.org

Here is the 1882 Skinner combination chuck patent"

Patent Images

Anyone know of another American combination chuck, new or old?

To be continued with modern European combination chucks.

Larry

The oldest chucks of this type that I have seen were invented by John H. Westcott of Oneida, NY in the late 19th century. I have seen a few of these, but never bought one. They looked more like museum pieces than something I would actually use and most were too big for my lathes. I never saw one of those chucks that still had the special wrenches with it. Westcott did not use a pinion gear to rotate the ring gear or scroll. The back of the ring gear or scroll had some blind holes and you needed a special wrench to adjust it.

Here is a Westcott company history:

Westcott Chuck Co. - History | VintageMachinery.org

And here is a list of Westcott patents:

Westcott Chuck Co. - Assigned Patents | VintageMachinery.org

Here is the 1873 Westcott combination chuck patent:

Patent Images

I have a couple of Skinner combination chucks, so Westcott did have competition in this area. To get their patent, of course Skinner had to find a completely different way of getting the same result as Westcott. I am not happy with the way the Skinner chucks operate, but they are about 100 years old, so maybe they were nicer when new. You can recognize one by the sliding knurled nut on the back of the chuck. They use a female square key. I have not researched all the Skinner patents, but I do know that Skinner was awarded two patents for two-piece reversible chuck jaws in 1891. I don't know if that was the first such jaw design for a heavy duty chuck. But American Watch Tool Co. had a watch lathe 3-jaw chuck design with 1881 patent dates that had two-piece non-reversible jaws.

Here is a Skinner ad from 1912 for their combination chuck that shows their patented jaw design:

Skinner Chuck Co. - 1912 ad - Skinner combination chucks | VintageMachinery.org

Here is the 1882 Skinner combination chuck patent"

Patent Images

Anyone know of another American combination chuck, new or old?

To be continued with modern European combination chucks.

Larry