Kincardine

Aluminum

- Joined

- Dec 29, 2007

- Location

- Kincardine, Ontario, Canada

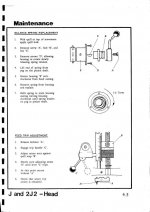

Hi folks, I need to replace mine in a 1969 Series 1 J head. I already have the new part from Hardinge.

What I wouldn't mind, is a bit of a walkthrough on this. Winding the spring, number of turns, etc. I would think this a common question.

If anyone can provide a link to this info, I will be very thankful!

Cheers, John

What I wouldn't mind, is a bit of a walkthrough on this. Winding the spring, number of turns, etc. I would think this a common question.

If anyone can provide a link to this info, I will be very thankful!

Cheers, John