Cdavid

Plastic

- Joined

- Jun 8, 2023

- Location

- Northeast PA

All: I am new to the forum. I am in the market to buy my first lathe and, armed with a little wisdom I gained from reading posts in this forum, I was able to somewhat competently inspect a machine today. I walked away from it, but would like your opinions on if I was being too critical.

It was a South Bend heavy 10. The ways looked decent. There was a very slight ridge on one of the V’s in the high wear area, but not enough for my fingernail to really grab. I also found a very, very slight ridge on the underside of the end stock. Cross slide had about ½ turn in backlash, and got more difficult to turn after passing the halfway point of its travel. If I positioned the carriage a little back from the headstock and tightened the carriage lock and backed off just enough for it to travel, the carriage got tight as I cranked it to the tail of the machine. Quick change gear lever needed to be held just right to get it to slide, which I figure is due to a worn bushing somewhere. No gears had any missing teeth. Lead screw had no variation in thread appearance across its length.

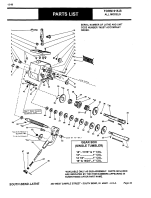

Now for the part that caused me to walk away. The cover on the lead screw end near the quick change gear box had been broken and brazed back together. I also found a crack in the apron on the headstock side. See photos:

I imagine these two damaged parts were the result of some bad occurrence. I could probably braze the crack in the apron, but I am worried that there might be some damage lurking elsewhere from the apparent incident that has yet to be discovered.

What would you experienced people conclude from my findings? The machine ran nice, and everything operated. Was I wrong to walk away from it? Is the apron crack not a big deal, and something that should just be brazed and forgotten about? Is the carriage binding as it moves to the rear of the machine when the lock is barley released while at the front indicative of serious wear that is not obvious to the eye?

I thank you for any thought you can offer. They would be valuable to me.

It was a South Bend heavy 10. The ways looked decent. There was a very slight ridge on one of the V’s in the high wear area, but not enough for my fingernail to really grab. I also found a very, very slight ridge on the underside of the end stock. Cross slide had about ½ turn in backlash, and got more difficult to turn after passing the halfway point of its travel. If I positioned the carriage a little back from the headstock and tightened the carriage lock and backed off just enough for it to travel, the carriage got tight as I cranked it to the tail of the machine. Quick change gear lever needed to be held just right to get it to slide, which I figure is due to a worn bushing somewhere. No gears had any missing teeth. Lead screw had no variation in thread appearance across its length.

Now for the part that caused me to walk away. The cover on the lead screw end near the quick change gear box had been broken and brazed back together. I also found a crack in the apron on the headstock side. See photos:

I imagine these two damaged parts were the result of some bad occurrence. I could probably braze the crack in the apron, but I am worried that there might be some damage lurking elsewhere from the apparent incident that has yet to be discovered.

What would you experienced people conclude from my findings? The machine ran nice, and everything operated. Was I wrong to walk away from it? Is the apron crack not a big deal, and something that should just be brazed and forgotten about? Is the carriage binding as it moves to the rear of the machine when the lock is barley released while at the front indicative of serious wear that is not obvious to the eye?

I thank you for any thought you can offer. They would be valuable to me.

.

.